Tasks, Tools & Technologies

Production Management

Production management is one of the most important management functions within manufacturing companies and crucial to economic success. In this article, we explain the most important tasks, tools and technologies of production management.

Table of contents

Definition

What is production management?

Production management refers to the planning, organization, coordination and monitoring of production processes within manufacturing companies. For these companies, production management is one of the most important elements of corporate management.

The aim of production management is to optimize the use of resources and the production processes themselves, thereby reducing costs, improving productivity and ensuring a high product quality.

To achieve this, people, production materials, machines, equipment and software systems must be coordinated effectively. The larger and more complex a company, the more challenging this task becomes.

In this article, we take a look at the most important tasks, objectives and tools associated with production management. Furthermore, we discuss technologies that are increasingly shaping production management – cloud computing and edge computing.

Note: Production management is often included within the slightly broader term “operations management”. The latter also considers the development and provision of services in addition to the production of physical goods.

Categorization

Strategic, tactical and operational production management

Production management can be divided into three levels: Strategic, tactical and operational production management. The main difference between these levels is their time horizon.

Strategic production management:

Strategic production management refers to the long-term production planning within a company. Generally, a period of up to 10 years is considered. The decisions that are made as part of strategic production management relate to long-term production goals, market entries, production sites and other longer-term projects.

Tactical production management:

Tactical production management involves the concrete implementation of strategic decisions, including for example the development of production capacities and the selection of new technologies. Usually a period of up to 5 years is considered.

Operational production management:

Operational production management involves practical, short-term production planning with regard to quantities, machine allocations and other factors. Additionally, this also includes the constant monitoring of production processes.

Main tasks

Which tasks are part of production management?

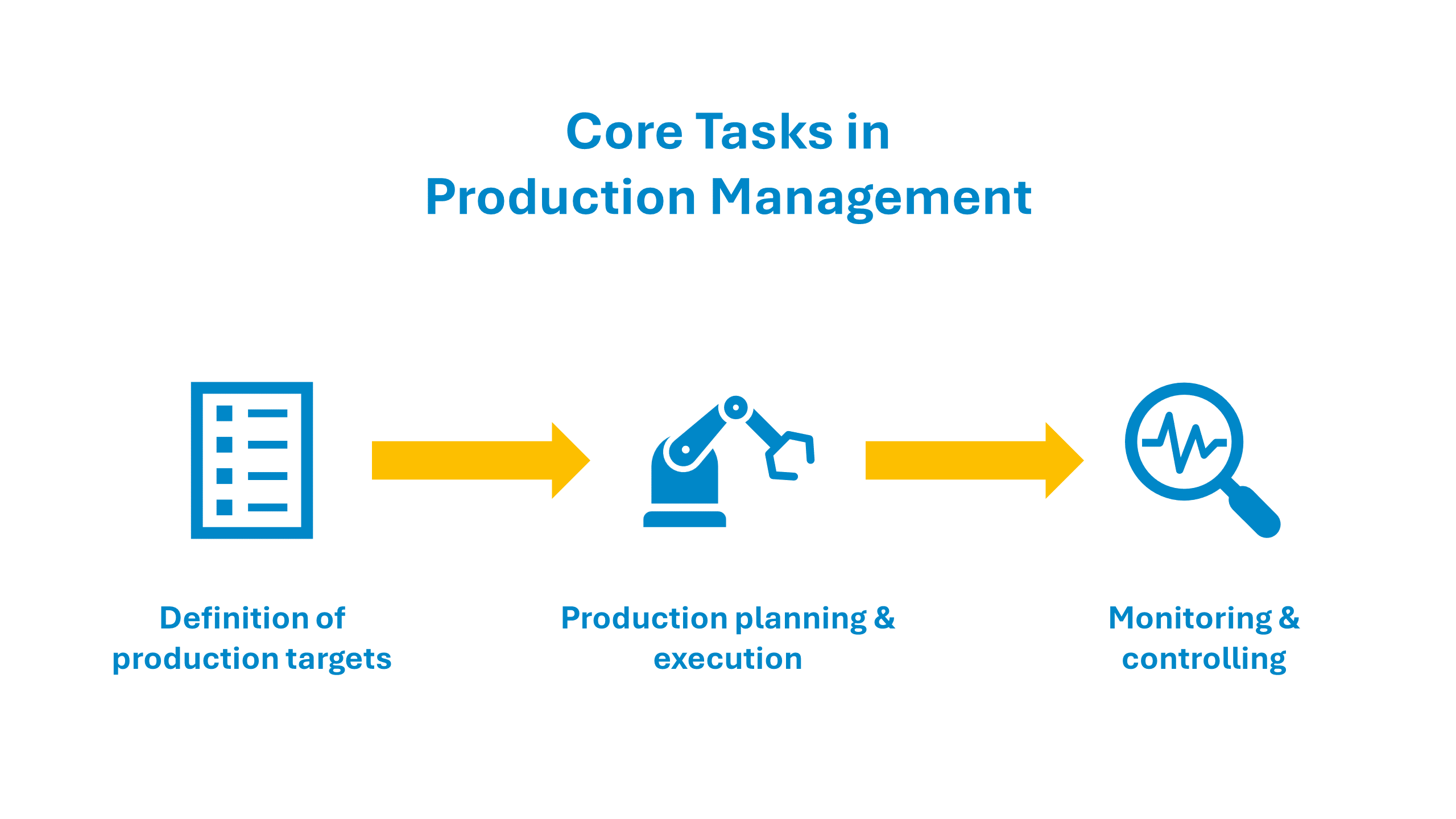

Production management consists of several core tasks. These include the definition of production targets, production planning and execution as well as the monitoring of a production.

Setting production targets

Setting long-term production targets is the responsibility of tactical and strategic production management. These targets depend on a wide range of factors, including the market and competitive situation of the company, the available resources as well as the company’s strategy.

Long-term production targets can be the introduction of new products, the establishment of new production sites or entry into new markets.

Production planning and execution

In production planning, a distinction can be made between long-term (strategic/tactical) and short-term (operational) planning.

As part of strategic and tactical production planning, measures are developed to implement the previously defined production targets. These include concrete decisions on production sites or the company-wide introduction of new technologies.

On the other hand, operational production planning and execution deals with the definition of specific quantities, the determination of material requirements and the concrete scheduling and capacity planning for the execution of orders. These tasks fall within the responsibility of production control, a segment of production management that deals with the operative implementation of broader production plans.

Monitoring

Another task included within production management is the constant monitoring of all production processes.

On one hand, a company wants to be able to react quickly to any bottlenecks, shortages, system failures, productivity losses or quality deficits. On the other hand, the goal is to identify potential for optimizations.

Operational monitoring of a production is carried out both automatically by software systems, which trigger corresponding messages in the event of deviations, and manually by checking machine status, key indicators or overviews. The prerequisite for effective monitoring of production processes is the seamless acquisition of machine and other production data.

Numerous production metrics and KPIs (key performance indicators) are also evaluated as part of medium to long-term controlling in order to monitor compliance with the previously defined production targets.

Digital production management in the cloud

With manubes, you are able to systematically automate production processes and visualize all areas of a production in real time.

The manubes platform offers worldwide access via web browser, easy operation and maximum security for production data.

Objectives & advantages

What are the goals of production management?

An effective and efficient use of production resources goes hand in hand with numerous economic benefits. The most important objectives of production management include the following:

Increasing production efficiency:

A central goal of production management is to increase production efficiency. Well thought-out and data-driven planning should maximize output while at the same time reducing costs for materials, personnel and other factors.

Optimizing the use of resources:

An important part of production management is to ensure that the available resources, including production machinery, materials and personnel, are utilized optimally.

Avoiding risks and failures:

Through constant and extensive monitoring of production processes, production management aims to identify and address failures, bottlenecks, quality deficits and other problems as early as possible.

Maximizing product quality:

Production managers carry out regular quality checks to ensure consistent and high product quality, thereby increasing customer satisfaction.

Improving internal and external collaboration:

The communication with other departments such as marketing or sales is another important part of production management, as is the optimization of cooperation with suppliers and other external partners.

Challenges

What are the challenges in production management?

Production environments are extremely complex, especially in larger companies.

Determining the number of units to be produced involves complex analysis and calculations where many different factors have to be taken into account (order backlog, market conditions, available capacities, etc.). The relevant data must be collected in its entirety and made available in the right place.

Other challenges include the scarcity of resources and dealing with bottlenecks, constant competitive pressure and the increasing demand for sustainable products.

Tools

Software & technologies for production management

In order to manage the complex tasks associated with planning, executing and monitoring production processes, numerous tools are used. In this section we highlight some of the most important software applications and technologies utilized in production management.

Software

In the age of digitalization, almost all production management tasks are supported by specialized software applications and in some cases even taken over completely. Some of these software systems are used directly on the shop floor, where they perform tasks such as collecting machine data, while others are responsible for company-wide planning and administrative functions.

The most important and most widely used applications for production management include MES and ERP systems.

Manufacturing Execution System (MES):

A Manufacturing Execution System (MES) is responsible for the real-time collection and processing of operational, machine, product and employee data. It supports people who are responsible for the detailed planning, control and monitoring of production processes in their decision-making.

The Manufacturing Execution System is usually connected directly to the automation level and therefore has access to machine data. An MES provides data on machine utilization, throughput times or quality parameters. Additionally, it should be able to communicate with other systems and perform tasks such as transmitting information on the status of production orders to a higher-level ERP system.

In contrast to ERP systems, MES are characterized by their close proximity to production processes on the shop floor and their ability to record and process various technical parameters.

Enterprise Resource Planning (ERP):

The ERP system maps a company’s business processes and resources and supports their planning, management and supervision. It usually also offers options for internal and external communication.

Typically, an ERP system consists of several modules for different sub-tasks. Many of these support production management, including material planning and warehousing, order management or personnel planning.

The individual requirements of an ERP system depend on factors such as industry sector or company size. In practice, it is often adapted to the specific needs of the company. In addition, many providers have sector-specific solutions.

Cloud Computing

Cloud technology offers numerous advantages for production management and has become an integral part of modern companies. Software such as ERP systems (e.g. SAP), databases (e.g. InfluxDB) and many others are increasingly being operated in the cloud, often as part of a „Software-as-a-Service“ (SaaS) offering, where the infrastructure and software used is managed by a third-party provider.

Cloud applications offer the following advantages:

- Easy access: Cloud applications allow location-independent access via web browser where the only requirement is a stable internet connection. This way, different people in a company are easily able to work together in the same environment even if they are located all over the world.

- Security: Thanks to the high security precautions taken by cloud providers and the use of modern encryption and authentication technology, established SaaS cloud applications often provide a high level of security.

- Lower costs for infrastructure and maintenance: Another advantage of cloud-based SaaS applications is that the underlying infrastructure is managed by the provider itself. Software updates, bug fixes and automatic backups are commonly included.

- Scalability: Many cloud applications can be easily scaled (storage space, users, range of functions, …). At the same time, end users often only pay for resources that they actually use.

manubes, our new platform for digital production management, offers all the benefits of modern cloud computing. Users can access the platform from anywhere in the world and gain access to a variety of innovative features. Additionally, manubes implements an extensive security concept.

Edge Computing

In edge computing, data is collected in close proximity to the data source and processed in real time (at the “edge” of the network). Edge technology is used in many different areas, including autonomous driving, home automation and virtual reality. But it also offers key benefits in industrial production.

Local pre-processing of machine data can reduce the amount of data that needs to be transmitted to a data center. This not only leads to lower bandwidth utilization, but also enables real-time reactions based on the data collected.

In practice, edge computing is often combined with cloud computing, with part of the data being processed directly on site while the cloud continues to serve as a central data aggregator.

Our cloud platform manubes utilizes edge technology to collect data from machines, devices, APIs and other production systems and securely transfer it to the cloud. You can find more information on our page about system integration with manubes.

Conclusion

The future of production management

While the core functions of production management are likely to remain the same, the specific workflows, tools and best practices are subject to constant change.

On one hand, production management is adapting to the changes in production itself. At the same time, the number of available tools is also growing: New software applications, technologies and other tools make it possible to evaluate even more production data, identify new potential and implement a multitude of optimization measures.

In order to remain competitive, manufacturing companies are required to evaluate new technologies and developments and regularly re-assess existing processes.

Discover manubes!

Cloud-based production management with manubes: Our innovative platform offers specialized tools for connecting production systems, managing and visualizing production data and automating production processes. manubes users benefit from a powerful infrastructure, worldwide access and maximum security.