Definition & Examples

Discrete Manufacturing vs. Process Manufacturing

Discrete manufacturing and process manufacturing are two fundamentally different types of production. We explain the key differences.

Definition: Discrete Manufacturing

What is discrete manufacturing?

Discrete manufacturing is a type of production in which distinct individual products are manufactured.

Each product typically consists of separate components that are defined in a bill of materials and assembled during the manufacturing process.

The final products are countable. Multiple product variants are common.

Examples of discrete manufacturing:

- Automotive production

- Furniture manufacturing

- Household appliance production

Definition: Process Manufacturing

What is process manufacturing?

In contrast, process manufacturing produces goods that are not countable but are measured by quantity, volume or weight.

Instead of bills of materials, process manufacturing uses recipes and formulas. These specify how and in what proportions ingredients must be processed to achieve the desired end product.

Examples of process manufacturing:

- Beverage production

- Paints and coatings manufacturing

- Metal processing

- Chemical industry

Differences

Differences between discrete manufacturing and process manufacturing

The fundamental differences between the products of discrete manufacturing and process manufacturing (countable units vs. homogeneous quantities) also lead to differences in production planning, the tools used and various other aspects.

Below, we highlights areas in which discrete manufacturing differs from process manufacturing.

Disassembly into individual components

In a discretely manufactured product, the individual components are often visible in the final product and products can often even be disassembled into their individual parts.

In contrast, with process-manufactured products – such as those created by mixing various ingredients – this is generally not possible.

Bills of materials and routings vs. recipes and formulas

Bills of materials are used in discrete manufacturing and provide a structured list of all components, assemblies and materials required to produce a product. Routings describe the necessary steps in the manufacturing process, including sequence, workstations and tools.

In contrast, process manufacturing relies on recipes and formulas. Recipes specify the required materials or substances for producing a product, including information on proportions and concentrations. Formulas describe the production process and provide details on how variables like pressure, temperature or mixing times must behave (often automated).

Types of manufacturing

In process manufacturing, products are often produced in batches. A batch is a defined production quantity manufactured under consistent conditions. Batch numbers make it possible to trace products back to their batch even after packaging (e.g. bottled beverages). Batches not only ensure consistency but also offer the advantage of traceability.

Discrete manufacturing features different types of production. In single-item manufacturing, each product is made individually. In series production, a fixed number of identical products is produced. Lastly, mass production refers to the continuous production of identical products in very large quantities.

Flexibility and degree of automation

Many discrete manufacturing processes offer a certain level of flexibility when producing different products or product variations. This could be achieved by retooling existing equipment or adapting manual assembly processes.

Process manufacturing typically offers less flexibility but often ensures high process stability. Many process industries are heavily regulated and not only the products but also the production processes themselves are continuously monitored. The degree of automation is usually very high.

ERP systems

In both discrete and process manufacturing, the ERP system is central to production planning. However, typical ERP systems for discrete manufacturing differ significantly from those used in process manufacturing.

ERP systems for discrete manufacturing manage bills of materials, routings and engineering data. They are often more order-driven and include configurators to handle different product variants.

ERP systems for process manufacturing must be able to work with recipes, quantities and units. They integrate functions for batch management, documentation capabilities and are often connected to laboratory information management systems (LIMS).

manubes

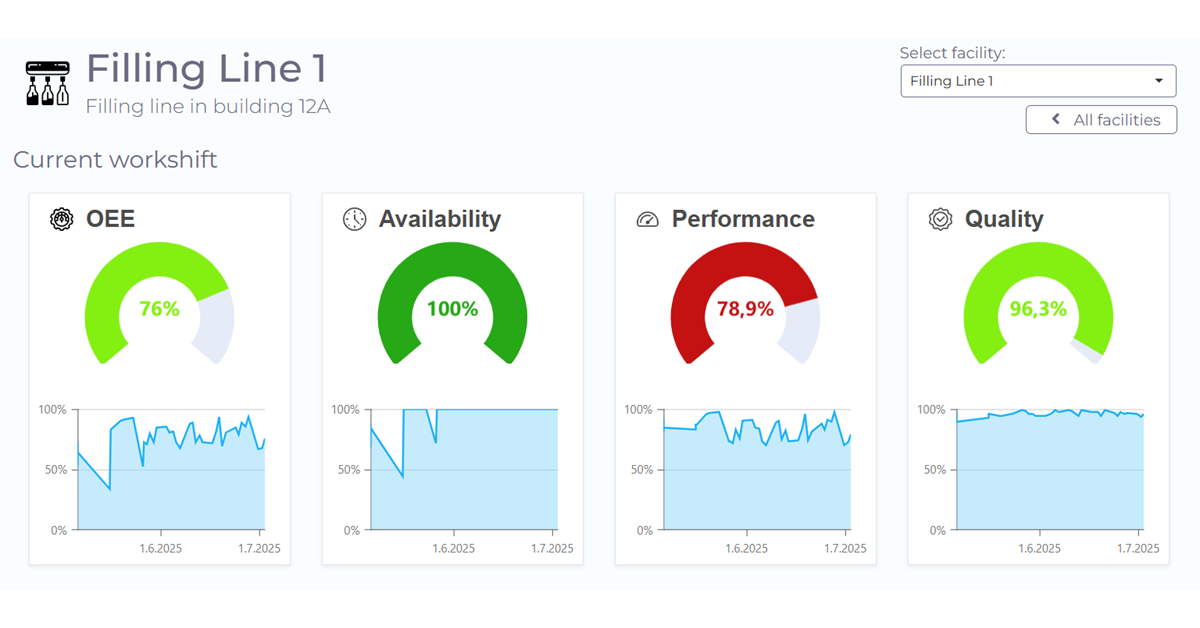

Flexible application development for discrete manufacturing and process manufacturing

Our manubes platform integrates intuitive no-code design tools for data models, visualizations and workflows. This allows manufacturers to quickly develop their own applications, tailored exactly to their specific requirements.

manubes utilizes edge components and industrial standard interfaces to facilitate data exchange with machines and devices, databases. shopfloor systems and IT applications such as ERP or LIMS.

Both companies in discrete manufacturing as well as process manufacturing benefit from a more effective production management with manubes.

Example applications:

Example of an OEE dashboard with manubes

Try manubes for free

Test the different manubes features in your personal cloud environment.