Methods, Tools & Example Measures

Continuous Improvement Process (CIP)

The Continuous Improvement Process (CIP) is an approach in production optimization that aims to gradually improve existing processes.

Definition

What is the Continuous Improvement Process?

The Continuous Improvement Process (CIP), also called Continual Improvement Process, is an approach for identifying and implementing improvements within organizations. The concept focuses on making small, incremental optimizations step by step, usually implemented locally through teamwork. CIP poses a contrast to large-scale, management-driven innovation projects.

Employees identify problems and propose improvements for their respective areas, which are then evaluated and, if appropriate, implemented as part of a structured process. The goal of CIP is to accelerate the implementation of improvements, but also to increase adoption and satisfaction among employees.

CIP is generally pursued on an ongoing basis and is not limited to a specific time frame. It requires not only clear structures and responsibilities, but also needs to be actively lived as a philosophy. Employees must be clearly signaled that feedback is welcome and leads to long-term improvements. More detailed information on implementation can be found in the section “CIP – Identification and implementation of improvements.”

Origins of Continuous Improvement – From the Toyota Production System to a Leading Quality Management Concept

CIP is considered one of the fundamental principles of quality management and is an integral part of the ISO 9001 quality management standard. The approach originated at Toyota, where it became a core corporate philosophy and a key element of the manufacturing process under the name Kaizen. Today, CIP is widespread across a wide range of industries and business functions, in some cases also known under terms such as Lean Management and Lean Production.

Implementation Workflow

CIP – Identification and implementation of improvements

The concrete implementation of the Continuous Improvement Process is not tied to specific methods or structures. Most importantly, it requires a well-defined workflow with unambiguous responsibilities and active involvement of the relevant teams.

The following steps are typical of CIP initiatives:

1. Continuous assessment of the status quo

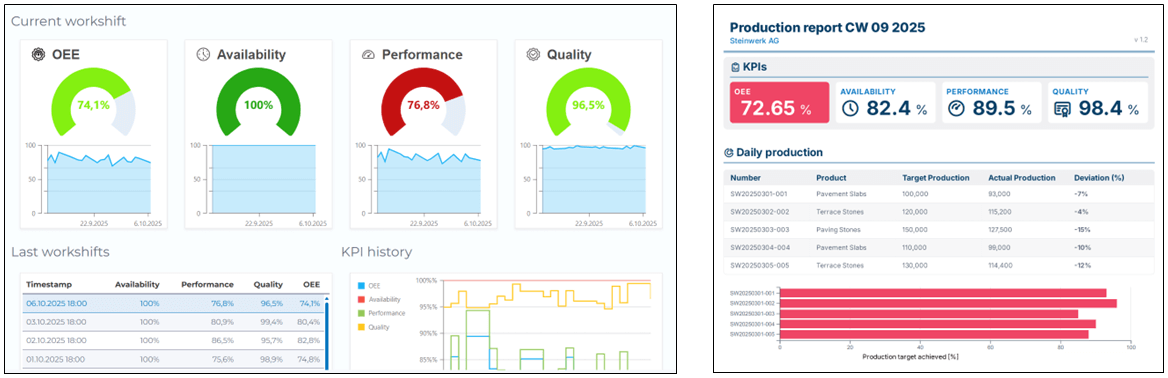

Transparency is one of the fundamental prerequisites for successful CIP implementation. Suitable key performance indicators (e.g. OEE, reject rate, downtime) provide data-based insights into a company’s current state and highlight potential areas for improvement.

At the same time, they support the evaluation of improvement proposals and the expected benefits, e.g. by using benchmark figures from other sites.

Dashboards and production reports can offer detailed insights into equipment performance. The image above shows an OEE dashboard and report created with manubes.

2. Identification of problems or improvement potential

Employees identify problems, suboptimal processes and improvement potential within their own areas or departments – often based on daily experience and in-depth process knowledge which the CIP approach specifically tries to leverage. Additional impulses can come from benchmark data (previous periods, other departments, …) and exchanges within the team or with customers.

Examples of potential issues:

- Waste (overproduction, excessive waiting times, transport times)

- Quality issues

- Safety or ergonomic deficiencies

- Incomplete training materials

3. Development of proposed solutions

The CIP approach places a strong emphasis on teamwork. Solutions are often developed collaboratively (e.g. in team-specific or cross-functional workshops), using methods such as brainstorming.

The developed solution approaches can be grouped into various categories:

- Process changes

- Adjustments to the work environment (including production layout)

- Standardization

- Technical aids

4. Evaluation of proposed solutions

Submitted proposals are reviewed systematically. Criteria include feasibility, effort and expected benefits as well as specific risks or sustainability aspects.

The evaluation process can be supported and streamlined by different methods, e.g. through scoring systems. Possible tools could be utility-value analyses, effort-benefit matrices or pilot trials on individual machines.

5. Derivation of concrete measures and assignment of responsibilities

Teams derive concrete implementation tasks from the accepted proposals and assign them to the responsible employee(s).

Current status and other information is typically managed using tools such as CIP boards or project management software:

- What exactly will be done?

- By when?

- Who is primarily responsible and who provides support?

6. Evaluation of results and success

The subsequent evaluation of implemented measures is a central element of CIP and ideally leads to insights that influence future initiatives. Data should also be incorporated at this stage, such as changes in scrap rates, downtimes or customer satisfaction surveys (before-and-after KPIs).

In addition to the degree of target achievement, companies should also document any side effects (positive or negative).

Depending on the outcome, measures may be integrated into existing standards or rolled out to additional sites. In some cases, a decision is made to adjust the measures or to initiate a new CIP cycle.

Methods

Methods and tools for Continuous Improvement

As a framework concept for production optimization, the Continuous Improvement Process does not prescribe a fixed methodology.

Nevertheless, there are several methods that are closely associated with the CIP approach. All of the methods listed below originated in Japan and are widely used in many organizations to support CIP:

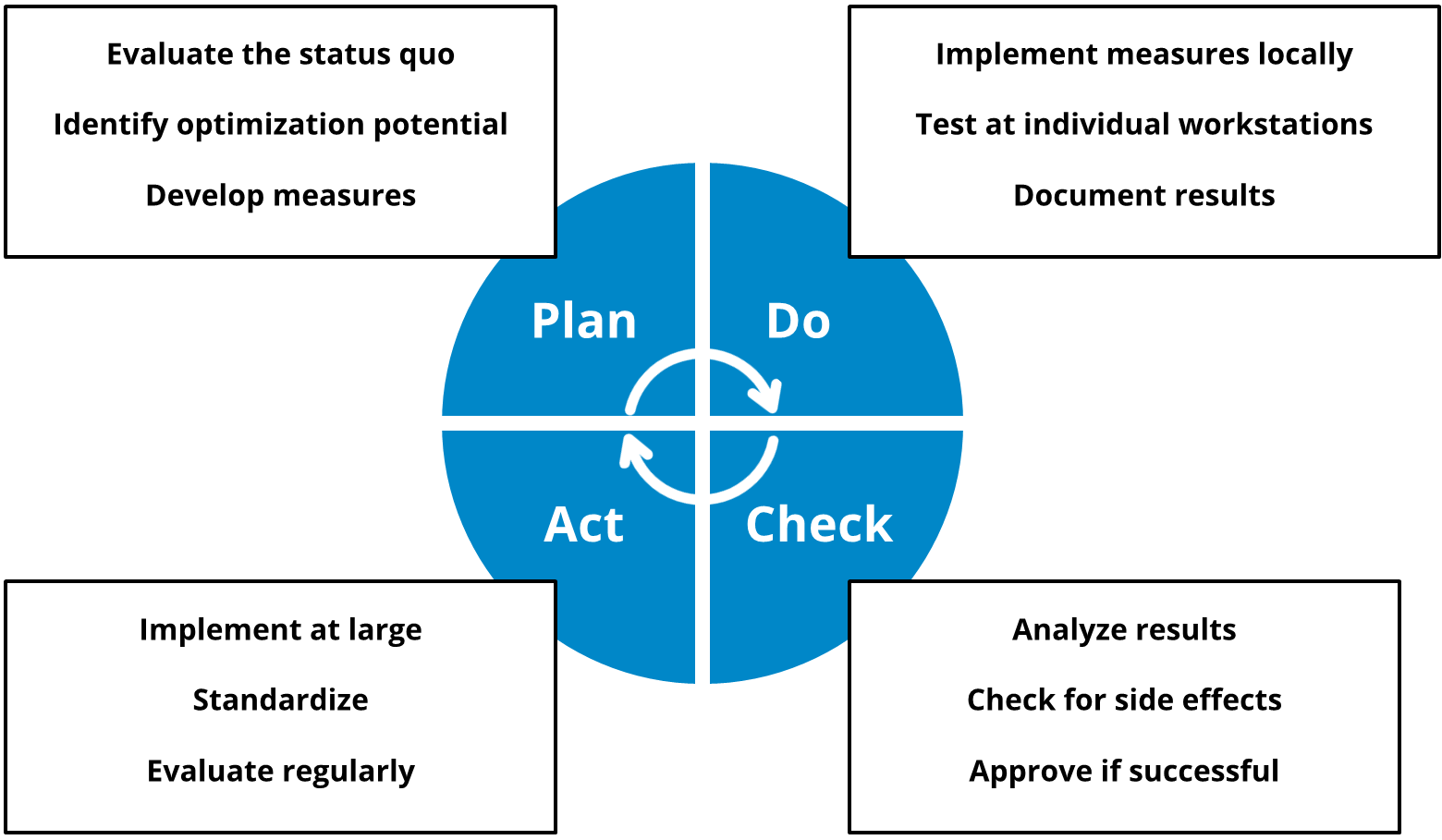

PDCA cycle

The PDCA cycle has been closely associated with the Continuous Improvement Process from the very beginning. PDCA stands for Plan, Do, Check, Act and describes an iterative process for implementing improvement measures.

The primary focus is on scaling successfully validated optimization measures to additional areas. This makes the PDCA cycle particularly suitable for organizations that want to test improvements on a smaller scale first and then roll them out across the company.

Phases of the PDCA cycle

- Plan:

Identify opportunities, analyze the status quo and develop an optimization concept – all in collaboration with local teams. - Do:

Implement the concept locally (e.g. at individual workstations) and improve it incrementally. - Check:

Carefully evaluate the results of the local tests, check for side effects and, if successful, approve large-scale implementation. - Act:

Implement and standardize the concept company-wide, integrate it into existing processes and materials, and regularly evaluate the results.

The process then returns to the planning phase again.

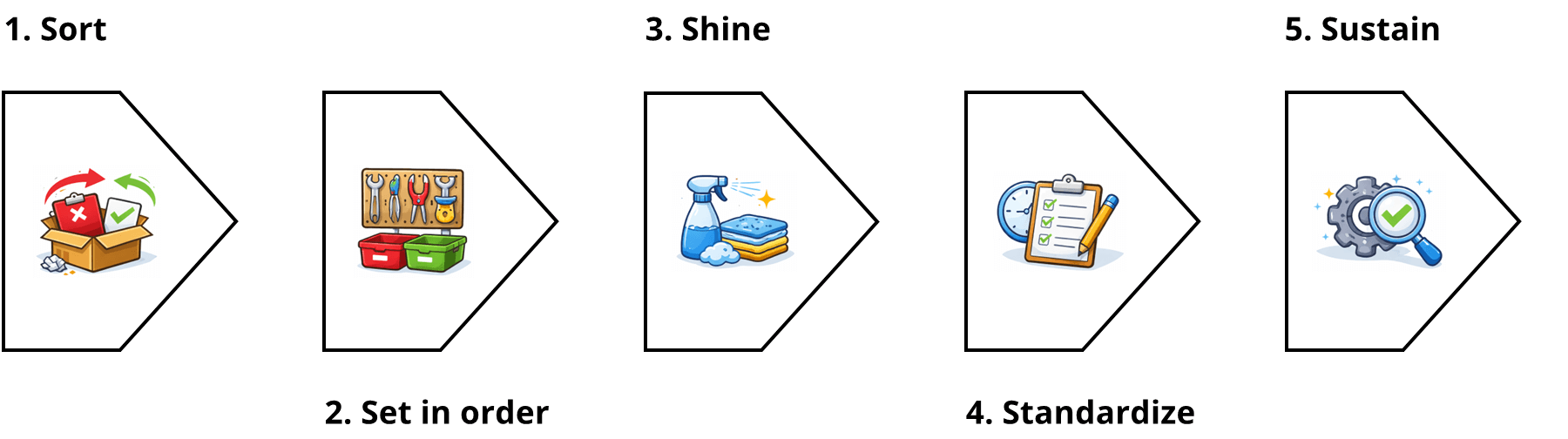

5S method

The 5S method is a workplace organization tool that is primarily used in manufacturing. The five steps Sort, Set in order, Shine, Standardize and Sustain are intended to improve workplace organization and efficiency, cleanliness and safety.

The 5S are originally based on the Japanese words seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾).

The aim is to achieve improvements such as reduced setup times, transport times and waiting times (e.g. through faster access to tools), as well as enhancements in ergonomics and workplace safety and more efficient use of space.

Typical measures within the 5S method include:

- Removal of unnecessary items

- Optimized arrangement of tools and aids (based on employee feedback)

- Clear and unambiguous labeling of storage locations

- Systematic and regular cleaning activities

- Use of digital work instructions and digital access to information at the workplace

The 5S method is often applied in a way that new optimization cycles are carried out at regular intervals.

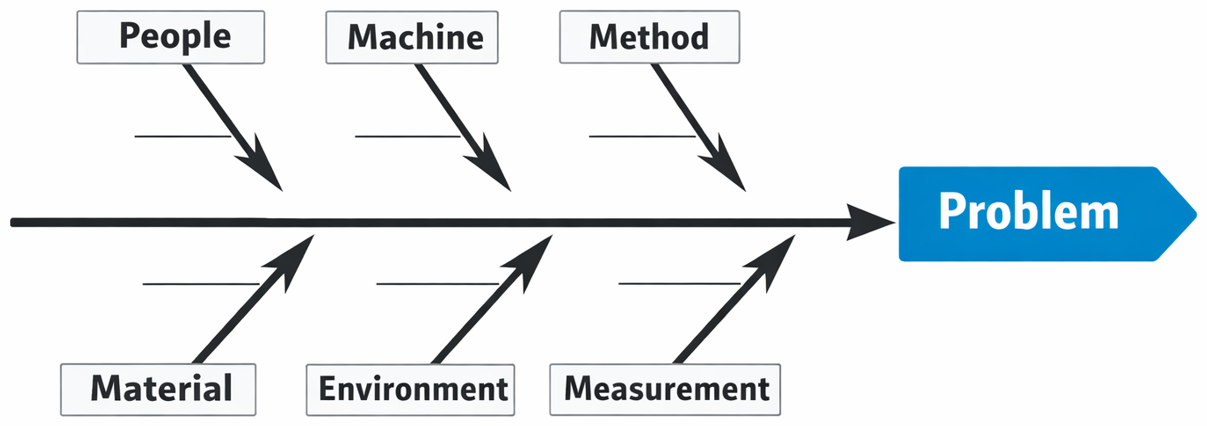

Ishikawa diagram (cause-and-effect diagram)

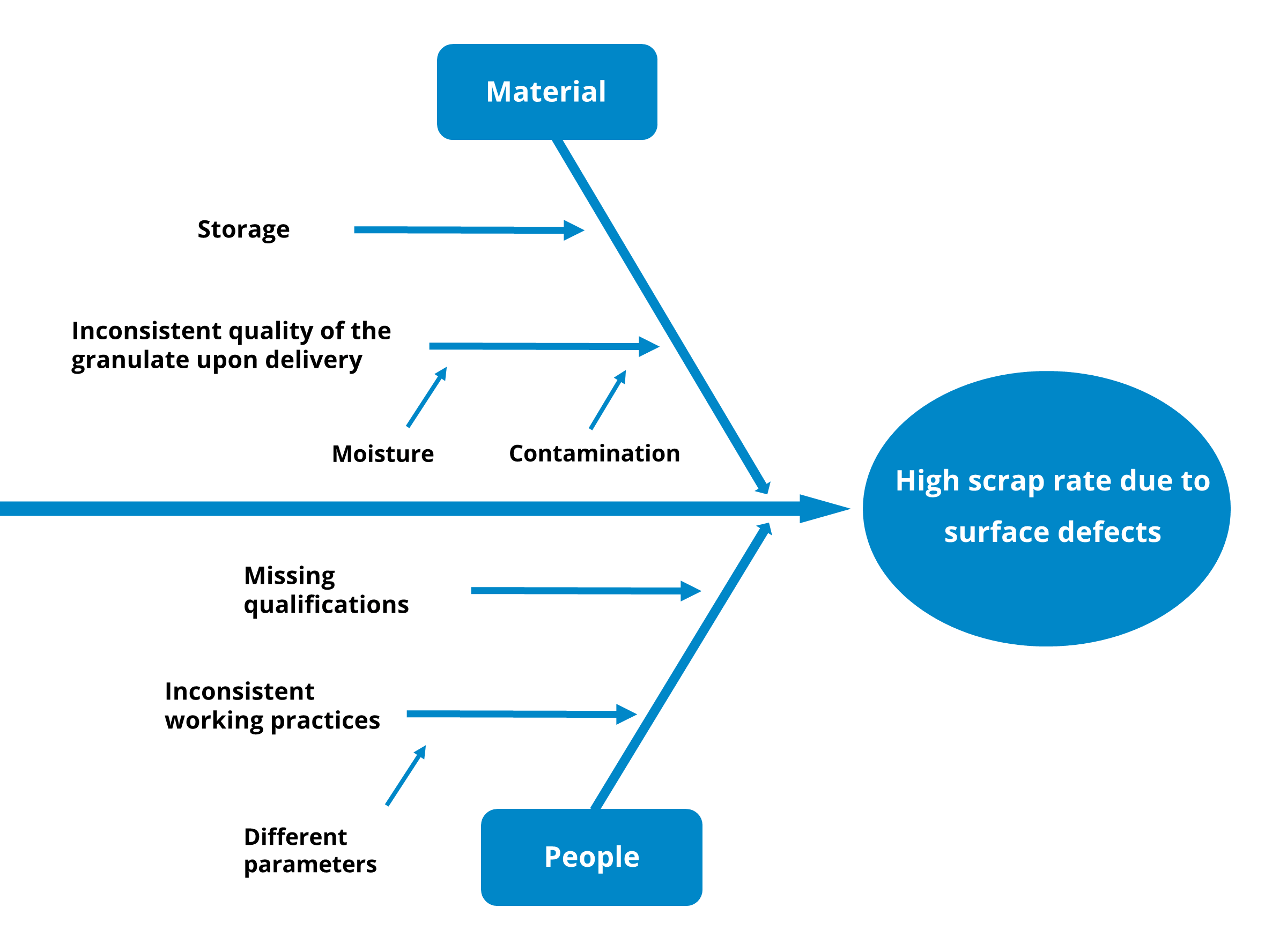

The Ishikawa diagram is a tool used to identify and structure the various causes of a problem or a desired outcome.

An example of the structure of an Ishikawa diagram is shown below. A horizontal main arrow points to an identified problem (or alternatively to a desired improvement).

The main causes of the problem are represented as arrows pointing diagonally toward the central main arrow (in this case, Material and People). Each main cause can in turn be broken down into associated sub-causes using smaller arrows.

The Ishikawa diagram is intended to help:

- Fully identify the causes of a problem

- Structure causes into main causes and subordinate sub-causes

- Determine the most likely causes of a problem

Categorization of causes according to the 8M framework

The 8M framework is a commonly used classification of root causes in manufacturing:

- Manpower / Mindpower

- Machine

- Material

- Method

- Measurement (environment)

- Management

- Mission

- Maintenance

The Ishikawa diagram and the 8M model support CIP in analyzing identified problems and improvement opportunities.

Objectives

Objectives of CPI measures

In general, the Continuous Improvement Process aims to reduce unnecessary material and time expenditure (waste), simplify and standardize workflows, improve the quality of products and services and create organized and safe working environments.

Possible CPI objectives:

- Increasing product quality

- Reducing waste

- Reducing downtimes

- Reducing transport and wait times

- Eliminating unnecessary tasks

- Improving workplace safety and ergonomics

- Enhancing employee skills and competencies

- Preserving and managing knowledge

CIP example measures:

Production optimization through digital tools

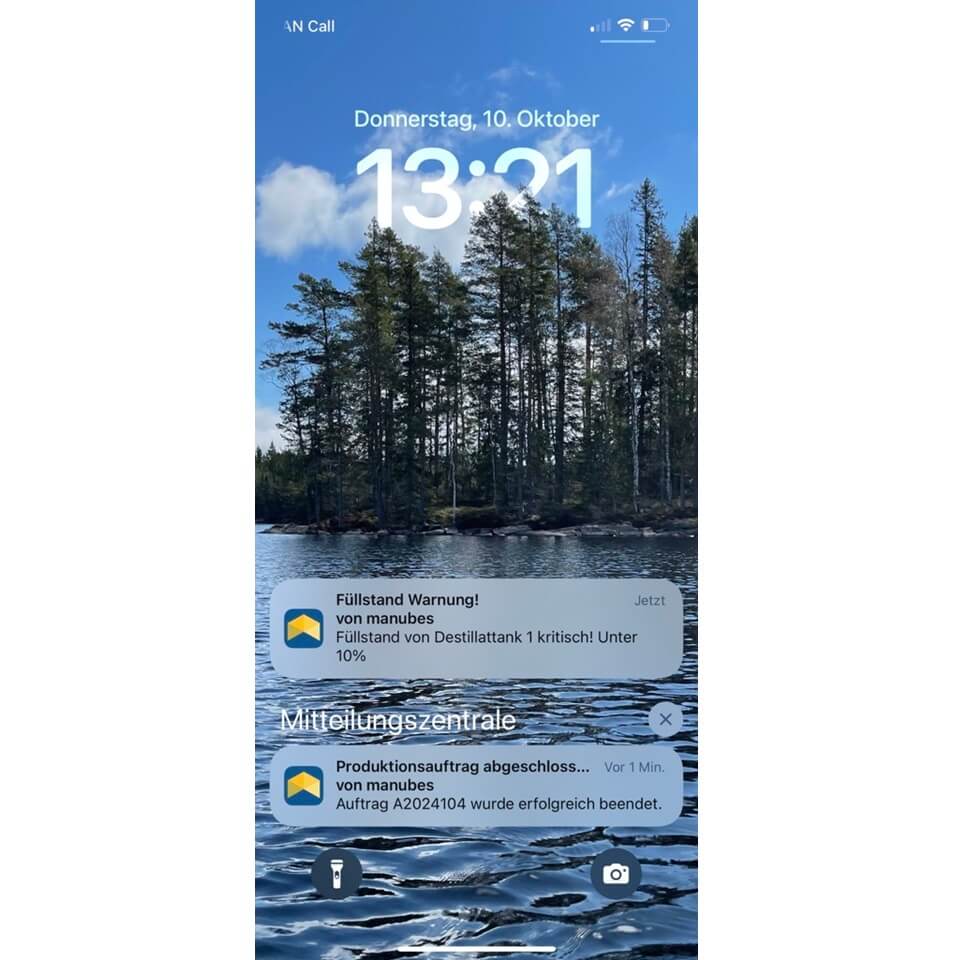

Custom notifications

and alarms

Mobile notifications and alerts can improve response times in production by informing responsible personnel more quickly. Triggers could include faults, changes in machine parameters, upcoming maintenance and incoming deliveries as well as production progress or other shift-related events.

Information retrieval

via QR code scan

QR codes on machines and tools can provide operating aids, configurations, or error codes – ranging from simple instructions to complete manuals and documentation. With manubes, you can manage information on a central platform and provide access through smartphones directly on the shopfloor.

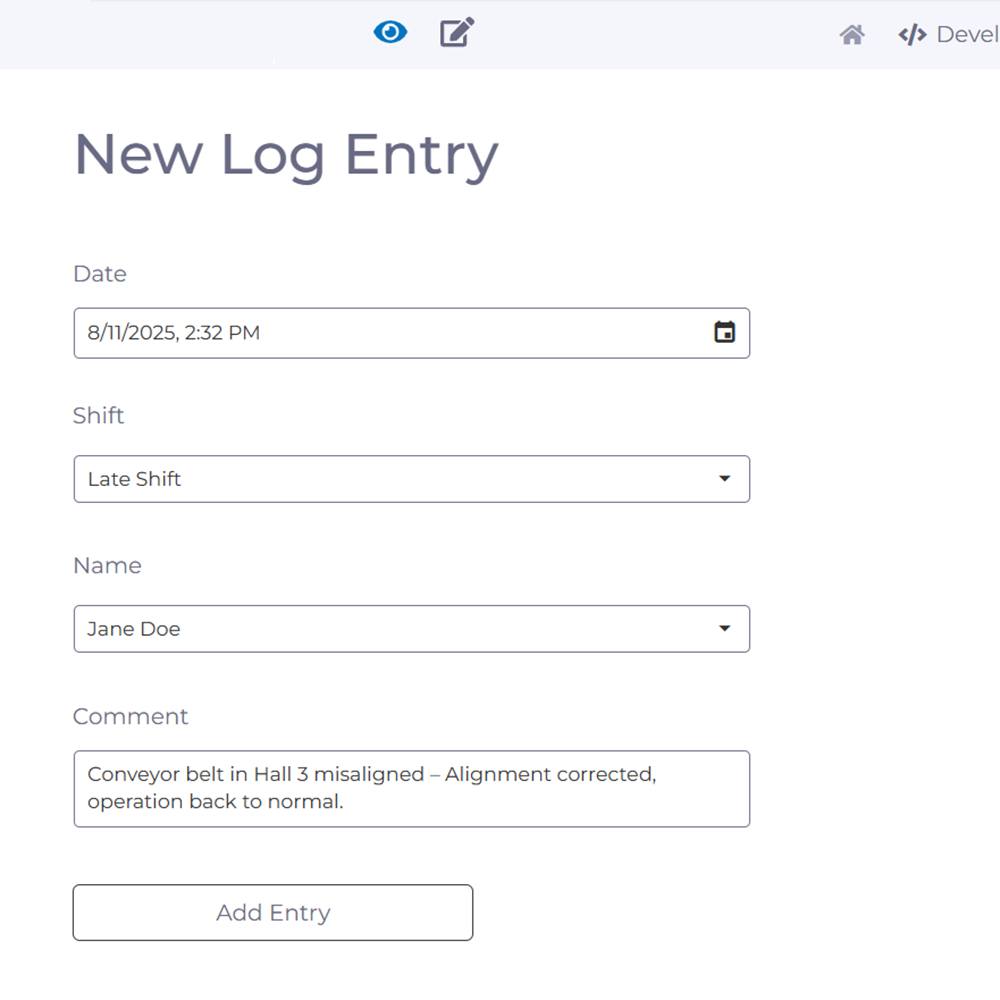

Digitally supported 5S audits

Digital tools can support the implementation of the 5S method. Regular workplace assessments conducted via smartphone or tablet can be enhanced with digital features such as photo documentation, checklists or notifications. This makes the evaluation process more consistent and allows measures to be tracked and standardized more easily.

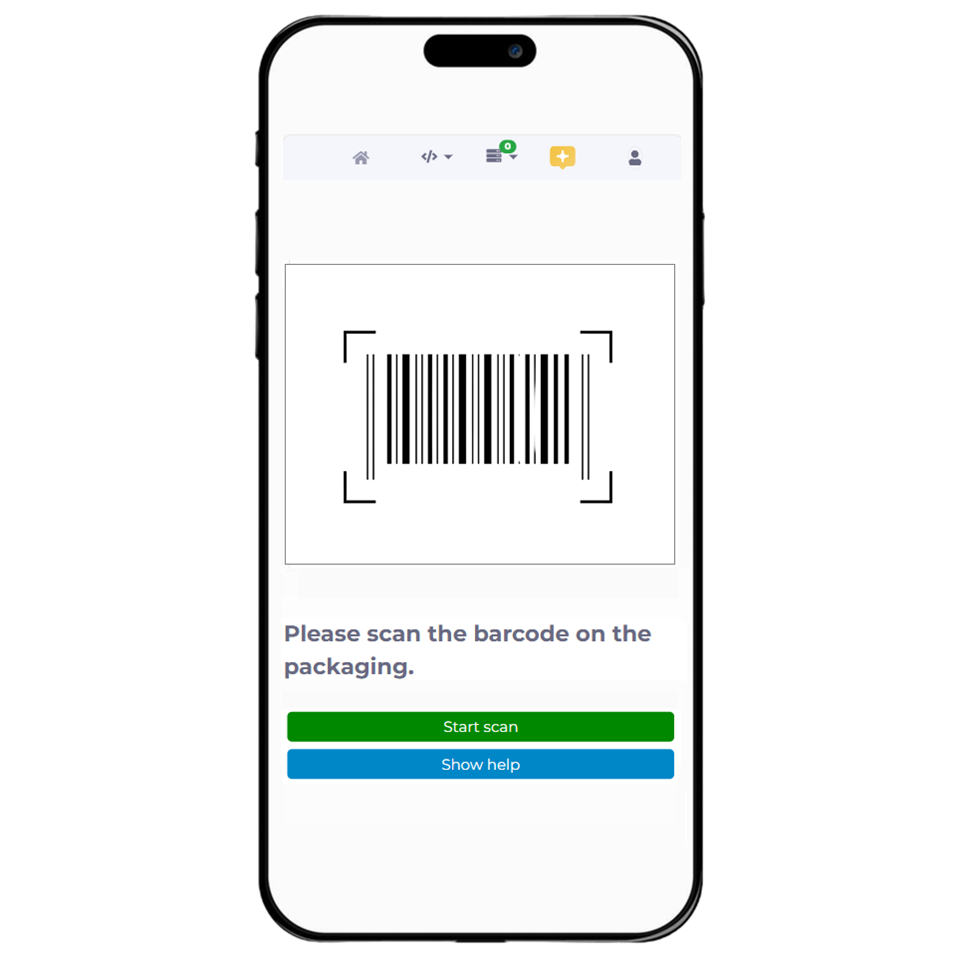

Material verification

through scans

By scanning raw materials, packaging and other materials before use, manufacturers can avoid mix-ups. In the background, an automated workflow cross-checks the data and confirms that the material corresponds the current order.

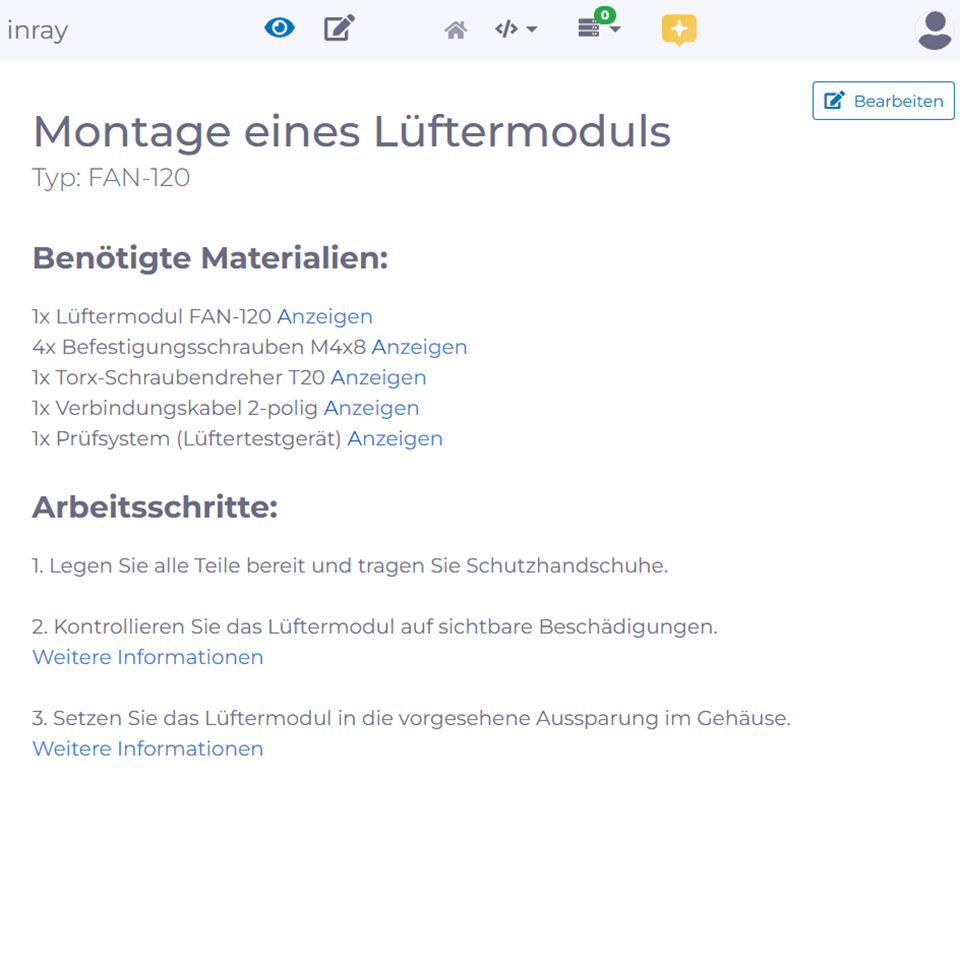

Digital

work instructions

Instead of paper binders and posted notices, work instructions can be provided digitally. This enables access on mobile devices, allows the integration of audio, video and interactive content, and makes it easier to keep instructions up to date and consistent.

manubes

Develop your own solutions – manubes as a platform for continuous improvement

manubes allows manufacturers to develop and manage innovative solutions on a central platform. Collect production data via standardized interfaces like OPC UA and create your own dashboards, workflow automations and custom applications.

With intuitive controls, access from anywhere and a wide range of powerful tools, manubes supports the Continuous Improvement Process (CIP) in industrial environments.

Try manubes for free

Test the different manubes features in your personal cloud environment.