Definition, tasks and software

Production planning

Production planning is a core component of production management and one of the most important tasks in manufacturing companies. It deals with the long-, medium- und short-term planning of all production processes. In this article, we explain the most important subtasks of production planning and show how various planning activities are enabled and supported by different software applications.

Definition

Definition: What is production planning?

Production planning is one of the main areas of production management and encompasses the long-term, medium-term and short-term planning of all production and assembly processes in manufacturing companies.

The most important tasks of production planning include planning the product range, production quantities, the required resources and the scheduling of production orders, taking into account the available capacities.

In order to complete these tasks, production planning has to coordinate effectively with other functions in the supply chain, including purchasing and sales as well as transportation and logistics.

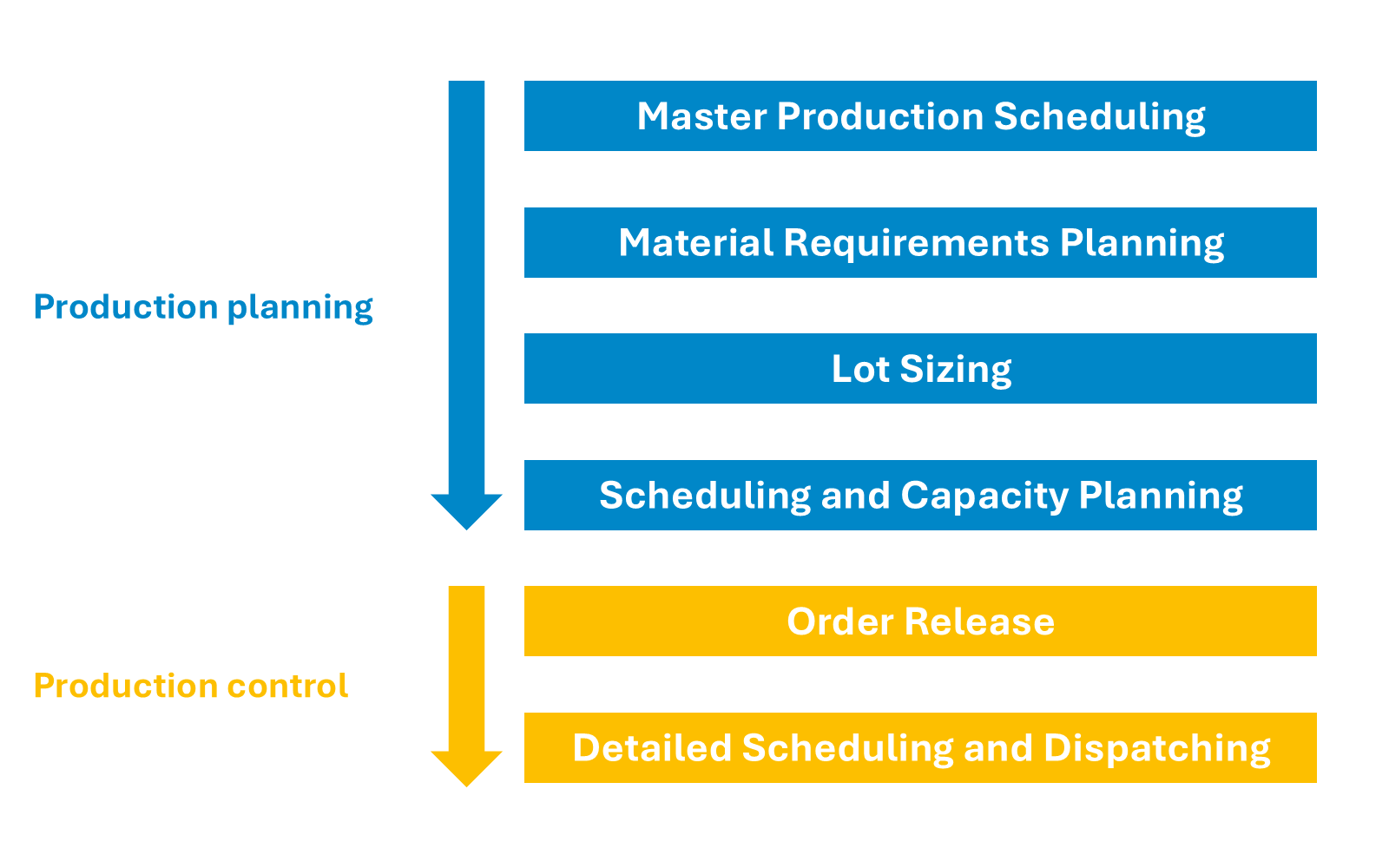

In practice, production planning tasks are directly followed by tasks related to production control. Both areas are therefore often combined under the term production planning and control and closely linked within the organizational structure of many manufacturing companies.

While production planning is responsible for all decisions, preparations and broader planning procedures in the run-up to production, production control deals with the operational implementation (e.g. release of production orders and allocation of specific resources).

Tasks

The different steps of production planning

Production planning is one of the most important tasks in manufacturing companies, but also one of the most complex. Even in smaller companies, the planning process must take a wide variety of factors and dependencies into account.

As the complexity of the production environment (e.g. coordination between plants, different machines and processing stations, complex manufacturing processes) and the products themselves (e.g. different product variants, individual customer orders, changing production quantities) increases, so does the complexity of production planning and its tasks. A clear breakdown of subtasks and responsibilities is therefore a basic prerequisite for successfully production planning.

For this reason, production planning is often divided into subtasks or steps that are carried out in sequence and build on each other (hierarchical models). Planning becomes more detailed with each step while referring to an increasingly shorter time horizon. At a certain point, the transition from production planning to operational production control takes place.

The exact design of the individual planning steps is highly dependent on the company. Examples of factors that influence production planning are industries and product types, different manufacturing processes, the degree of digitalization or the strength of demand fluctuations.

In the following sections, we explain the most important steps in production planning and their transition into production control.

Master Production Scheduling / Production program planning

Master Production Scheduling (MPS) or Production Program Planning defines the type and quantity of products to be manufactured (primary requirements) over a longer planning horizon. This includes finished goods, but also spare parts and marketable assemblies.

Production program planning is carried out on three levels: Strategic, tactical, and operational.

- Strategic production program planning determines the company’s long-term product portfolio and the markets it intends to serve. It typically spans several years.

- Tactical production program planning focuses on shaping the product assortment and product groups in more concrete terms. A typical planning horizon might be one year.

- Operational production program planning sets the production quantities of specific product variants over a shorter period (e.g. monthly or quarterly).

The basis for developing the production program includes forecasting methods, current customer orders, and historical data.

The exact procedure for master production scheduling depends heavily on factors such as company size and the type of products being manufactured. For instance, there are significant differences between companies that produce for stock and those that manufacture strictly to order.

Example Scenario 1: Automotive Manufacturer (Make-to-Order Production)

A major automotive manufacturer may begin by creating a rough sales plan based on demand forecasts, past sales data, and expert evaluations. This plan is then allocated across existing production facilities and further refined based on actual customer orders. The result is a detailed production program listing all end products to be manufactured within a specific time period. From this, production orders for the individual components are derived.

Example Scenario 2: Food Manufacturer (Make-to-Stock Production)

A producer of staple food items may primarily plan its production program based on make-to-stock principles. Using sales forecasts, seasonal demand fluctuations and current inventory levels, the company determines the quantities of products such as rice, pasta and canned goods to be manufactured over the coming months. The primary requirements are planned to ensure sufficient inventory is available at all times to meet market demand.

Example Scenario 3: Home Appliance Manufacturer (Mixed Production)

A manufacturer of home appliances like refrigerators and washing machines might adopt a hybrid strategy combining make-to-stock and make-to-order production. The production program for standard models is developed using sales forecasts and seasonal trends. At the same time, individual customer orders for customized variants or special editions are also considered. As a result, the production program includes both stock-keeping products for general distribution and order-specific products that are only manufactured after the order is received.

Material Requirements Planning / Secondary Requirements Planning

Secondary requirements planning determines which raw materials, semi-finished goods, components and subassemblies are needed to produce the previously defined master (primary) requirements.

This planning is based on bills of materials (BOMs) and routings (work plans) which contain detailed information about the structure of products and the necessary production steps and tools. These are broken down step by step into their individual components to derive the exact resource requirements.

Product components may either be produced in-house or procured externally.

In addition to determining material requirements based on the production program or BOMs, companies can make use of consumption-based planning for certain components. This method forecasts material needs for a specific period based on past usage data.

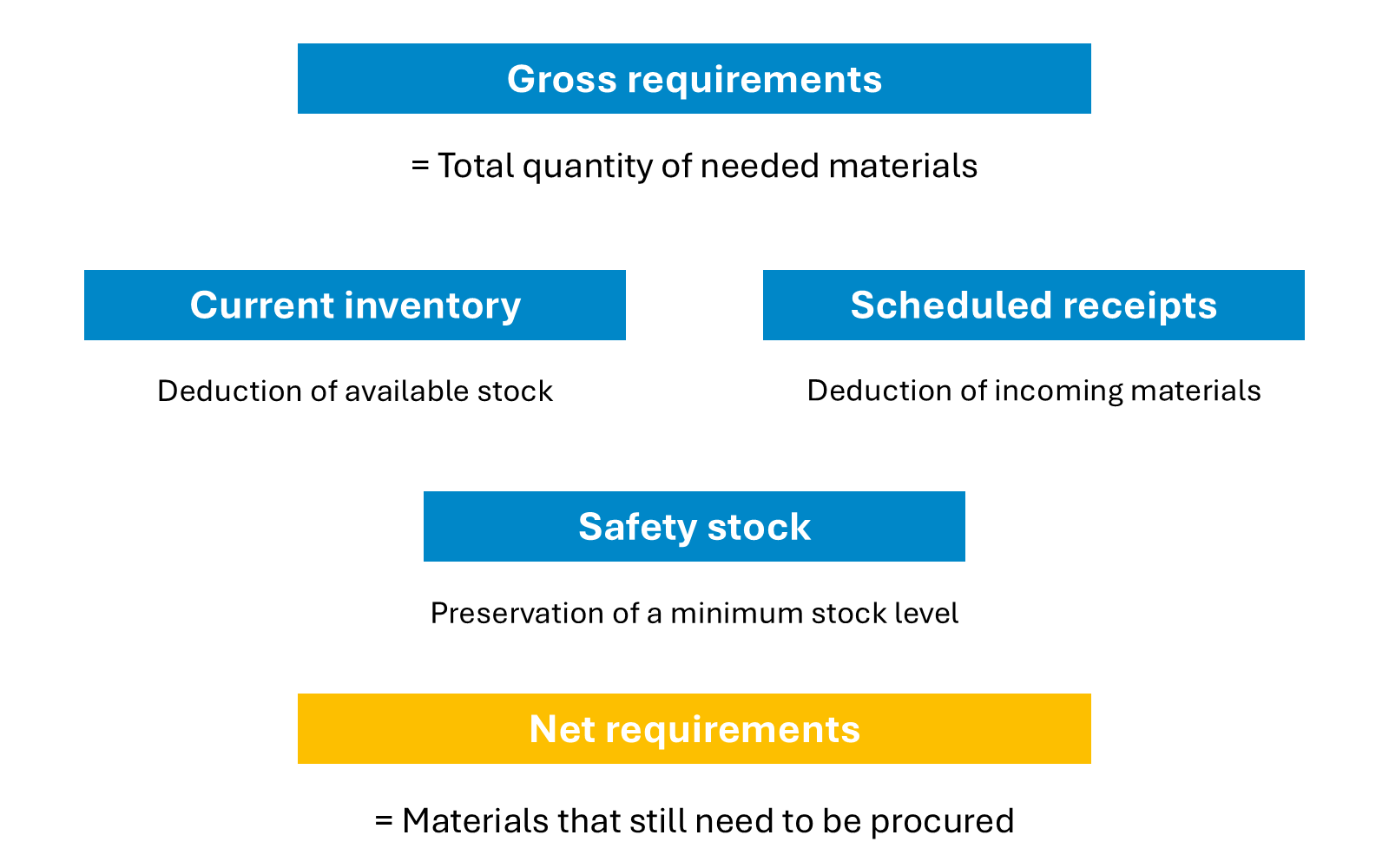

It’s also essential to consider current inventory levels as well as materials already ordered or reserved. As a result, a distinction is made between:

- Gross requirements – the total quantity of materials and components needed

- Net requirements – the quantity that still needs to be procured after accounting for available stock and pending orders

The secondary requirements needed for a given period are grouped into lots, which define the quantities in which materials are to be ordered or produced in-house (see Lot Sizing).

Based on the determined requirements, either production orders (for in-house manufactured components) or procurement orders (for externally sourced components) are generated.

Lot-Sizing

Lot Sizing determines how many products or components should be produced or ordered together – grouped into a production lot or procurement lot.

The optimal lot size depends on various factors. Smaller production lots may lead to needing more frequent machine setups or cleanings, while larger lots can result in higher inventory holding costs. In the case of procurement lots, factors such as minimum order quantities and lead times must also be considered.

Depending on the company’s situation and market conditions, lot sizes may remain relatively constant over time or be regularly adjusted to match demand (often with the help of mathematical models).

Scheduling and Capacity Planning

Scheduling and capacity planning generally consist of two main steps: Lead time scheduling and capacity planning.

Lead time scheduling:

As part of lead time scheduling, the earliest and latest possible dates for production orders are determined – initially as preliminary dates without considering available capacity. There are two main methods for this: Forward scheduling and backward scheduling.

In forward scheduling, the process begins with the earliest possible start date and calculates the earliest possible completion date based on that. This allows companies to check whether orders can be completed on time and identify potential buffer periods.

In backward scheduling, companies start from a fixed delivery date and work backward to determine the time required for each production step. This is done using routing data, which outlines the individual steps required to manufacture a product. The goal is to identify the latest possible start date in order to minimize inventory levels and tied-up capital, while still meeting promised delivery dates. As a downside, disruptions and unforeseen events can quickly lead to delays in completing the entire order.

Capacity planning:

The results of lead time scheduling are then compared with the available capacities, including equipment and personnel. If capacity is exceeded or underutilized, corrective actions can be taken. These may include rescheduling orders, adjusting lot sizes or acquiring additional capacity.

The outcome of scheduling and capacity planning is typically a rough production schedule that covers a time horizon of one to several months.

Order Release

Order release is already part of production control and follows the previous steps of production planning.

At this stage, covering a shorter planning horizon (e.g. 1–2 weeks), companies verify whether the necessary materials, equipment, and labor are available to execute the production orders scheduled for that period.

If all required resources are available, the order is released, the necessary documentation is generated, and resources are reserved accordingly.

Detailed Scheduling and Dispatching

The next step involves the most efficient allocation of released, previously only roughly scheduled production orders to the available workstations. The goal is to achieve high capacity utilization while meeting delivery deadlines and minimizing waiting times.

During machine assignment, factors such as machine costs may also be taken into account. Slower but more cost-effective machines may be prioritized if this helps avoid idle times or bottlenecks.

The result of detailed scheduling is a precise production schedule that specifies exact start and end times for each operation.

Optimize your production with manubes

manubes offers a central platform for production data management, data visualization and workflow-based process automation.

Manufacturers gain access to a variety of innovative tools in order to quickly develop their own applications – tailored to their requirements.

Software

Software for production planning

In practice, production planning is supported by various software systems, with a steadily increasing level of digitalization. More and more planning activities are now performed using specialized software functions rather than traditional paper-based methods as they used to in the past.

Emerging technologies such as Artificial Intelligence (AI) offer potential for further innovation in production planning – especially when it comes to detailed scheduling within complex manufacturing environments, where the number of influencing factors can quickly become overwhelming. In these cases, algorithms can not only improve the speed and quality of existing processes but also solve planning problems that would be infeasible to handle manually.

Among the most important software systems in production planning is the Enterprise Resource Planning (ERP) system. It manages a company’s resources across departments and supports a wide range of planning processes.

The more detailed production-level planning is facilitated by the Manufacturing Execution System (MES). In addition, systems such as Product Lifecycle Management (PLM), Advanced Planning and Scheduling (APS) tools and cloud-based platforms can support production planning in various ways.

The following section provides an overview of the key software systems used in production planning and their respective functions.

Enterprise Resource Planning (ERP Systems)

The ERP system is arguably the most important tool for production planning in most companies. As the term Enterprise Resource Planning suggests, an ERP system manages a company’s resources across departments. These resources include financial assets, personnel and materials, as well as accumulated knowledge from areas such as product development, marketing & sales and quality management.

Since much of this data is required at different points throughout the production planning process, the ERP system serves as a central interface for coordination between departments, making it an essential tool for planning teams.

In manufacturing companies, ERP systems integrate data from procurement, sales, inventory and other areas, forming the data foundation on which production planning is built.

In practice, ERP systems are often modular in structure, and the exact functionality can vary depending on the industry.

Note: Detailed shop floor scheduling is typically not handled by the ERP system. Instead, it’s usually supported by Manufacturing Execution Systems (MES). Unlike ERP, MES operates directly on the production floor. In a typical setup, the ERP system passes the output from rough scheduling and capacity planning (i.e. capacity-checked and tentatively scheduled orders) to the MES, which then provides feedback on production progress.

Key ERP functions in production planning:

- Management of bills of materials (BOMs), routings, formulas, and similar documentation

- Management of material and inventory levels (including finished goods)

- Tools for determining primary requirements

- Tools for calculating secondary requirements, including current purchase orders and inventory to determine net requirements

- Execution of purchase orders

- Creation and management of production orders, including resource reservations

- Tools for forward and backward scheduling of orders

- Personnel management

- Machine, tool, and workstation scheduling

- Cost calculation, including material costs, machine hourly rates, and labor costs

- Production data acquisition

- Monitoring, alerts, and reporting

For many of the functions listed above, specialized software solutions exist that often go beyond what a standard ERP system offers. Examples include: Product Data Management (PDM) and Product Lifecycle Management (PLM) for managing product-related data, systems for maintenance planning and documentation as well as software for human resource management.

Examples for existing ERP tools:

- Automatic reservation of machines and tools upon creation or release of production orders

- Graphical scheduling boards with drag-and-drop functionality for order allocation

- Sending inquiries to multiple suppliers to request quotes, followed by automatic conversion into purchase orders

- Inventory monitoring and automatic reordering when minimum stock levels are reached

- Lot and serial number traceability for full product tracking across the supply chain

PPS Systems

A PPC system (Production Planning and Control system) supports the various steps of production planning and control with specialized functionalities. In many companies, PPC systems are integrated into the ERP system, but they can also operate as standalone software solutions. In either case, they are closely linked to the ERP system to ensure coordination between production planning and the company’s broader resource management.

A PPC system typically supports all core tasks of production planning and control as outlined in the section on the components of production planning.

Typical Functions of a PPC system:

- Comprehensive data management: Management of bills of materials (BOMs), routings, inventory, maintenance data and more

- Master production scheduling: Forecasting tools, processing of customer orders

- Material requirements planning (MRP): Deriving material needs from BOMs, consumption-based forecasts, net requirements calculation based on inventory levels

- Lot sizing: Optimization tools that calculate lot sizes based on various influencing factors

- Procurement: Planning and execution of purchase orders

- Scheduling and capacity planning: Tools for forward and backward scheduling of orders, capacity checks against available machines and workstations, and proposing adjustments in case of conflicts

- Order release: Verifying resource availability, reserving capacity, and generating production documents

- Detailed scheduling: Assignment of production orders to specific machines or workstations

- Order monitoring: Tracking the progress of production orders in real time

PPC systems help ensure that production is efficient, cost-effective, and well-coordinated, erving as a crucial link between high-level business planning and operations on the shop floor.

Manufacturing Execution Systems (MES)

MES (Manufacturing Execution Systems) are also relevant to production planning. Typically, the MES supports the transition between the planning level (ERP) and the shop floor. Production orders created in the ERP system are forwarded to the MES for release and detailed machine-level scheduling.

This makes the MES responsible for detailed scheduling and execution at the shop floor level, enabling precise allocation of production orders to machines as well as the assignment of personnel and tools. The primary objective is to optimize the utilization of available capacities.

Unlike ERP systems, which operate at a higher, business-wide level and integrate data from various departments, the MES provides more detailed real-time insights into the actual state of production. For this, it needs to capture real-time data from machines and production lines – including e.g. data on machine run times, material consumption and production progress.

As a result, MES systems allow for quick, short-term responses to deviations or disruptions in the production process. In addition to their role in planning, MES typically cover large parts of production control and production monitoring.

To function effectively, MES and ERP systems must be tightly integrated through suitable interfaces that enable seamless data exchange. While the ERP system provides high-level planning results to the MES, the MES, in turn sends feedback on production progress and execution status back to the ERP system. In practice, this data exchange is often facilitated via APIs or standardized industrial communication protocols such as OPC UA.

Other software systems in production planning

APS systems:

Advanced Planning and Scheduling (APS) systems support scheduling and capacity planning with advanced functionalities. By taking a variety of factors into account, APS simulates different planning scenarios, allowing planners to explore alternatives and optimize scheduling decisions.

The goal is to use algorithms and optimization techniques to achieve more efficient allocation of orders – especially in complex environments where traditional methods may fall short. APS systems can help balance capacity, resources, and delivery commitments more effectively than standard planning tools and their use can lead to improved utilization, reduced lead times and increased on-time delivery performance.

SCM systems:

Supply Chain Management (SCM) systems manage the entire supply chain, including both supplier collaboration and the distribution of finished products. They support production planning primarily in the area of material procurement.

By improving coordination with suppliers, SCM systems aim to avoid capacity bottlenecks and optimize delivery times. They help ensure that required materials are available when needed, enabling smoother production processes and reducing delays caused by material shortages. Additionally, they provide transparency across the supply chain, allowing for better forecasting, risk management and responses to disruptions.

Analysis and reporting tools:

Applications in data analytics and Business Intelligence (BI) support production planning by providing key performance indicators (KPIs) such as production efficiency, capacity utilization or Overall Equipment Effectiveness (OEE).

These insights serve as a basis for strategic decision-making, especially in long-term master production scheduling. By identifying trends, inefficiencies or recurring bottlenecks, BI tools help planning teams make more informed choices, improve resource allocation and align production strategies with business goals.

Conclusion

Production planning summed up

Production planning – especially in larger companies – covers a broad and complex range of tasks that span multiple departments. To provide structure, hierarchical models have been developed that break production planning down into interrelated sub-tasks (see: The different steps of production planning).

The exact design and implementation of each step depend on factors such as the type of products being manufactured and the company’s size and organizational structure.

Various software systems are used to support these processes, with a combination of ERP and MES typically forming the core of production planning.

Try manubes for free

Test the different manubes features in your personal cloud environment.