OPC Unified Architecture

What is OPC UA?

OPC UA is an open communication standard for exchanging data in industrial settings. This article will give you a detailed and beginner-friendly introduction to the basics of OPC UA. In addition to the functionality and the most important features of the OPC UA standard, we will discuss information modeling and specifications as well as the importance of OPC UA for the industry.

Definition

What is OPC UA?

OPC UA stands for OPC Unified Architecture and is a vendor-independent, cross-platform communication standard for data exchange between machines, devices, and software applications in industrial environments.

With the help of OPC UA, complex data from industrial controllers and other sources can be provided in a standardized format and retrieved and processed by a wide variety of applications. OPC UA also provides an interface for managing and automating processes.

How does OPC UA communication work?

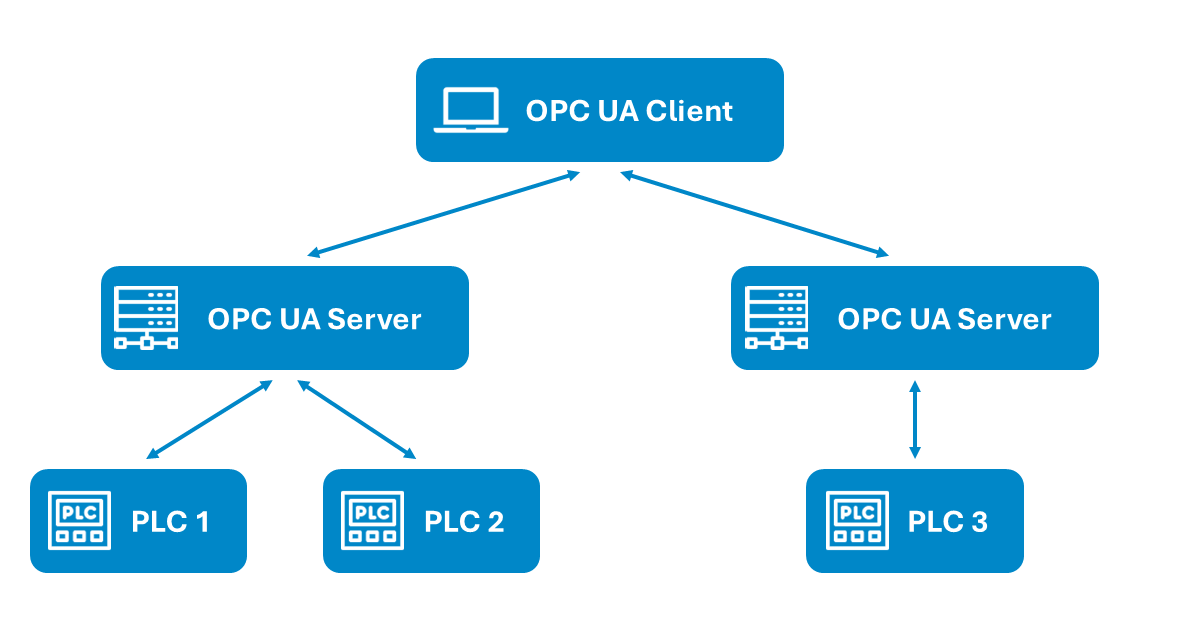

OPC UA is based on a client-server model:

- An OPC UA server provides data from one or more sources (e.g. Programmable Logic Controllers).

- IT applications such as MES (Manufacturing Execution System), ERP systems (Enterprise Resource Planning) or cloud platforms use OPC UA client software to retrieve the required data from the OPC UA server, transmit data themselves or interact with the source in other ways.

OPC UA servers provide information in the form of a hierarchy of objects, data points, and methods, with the option to implement device- and industry-specific models.

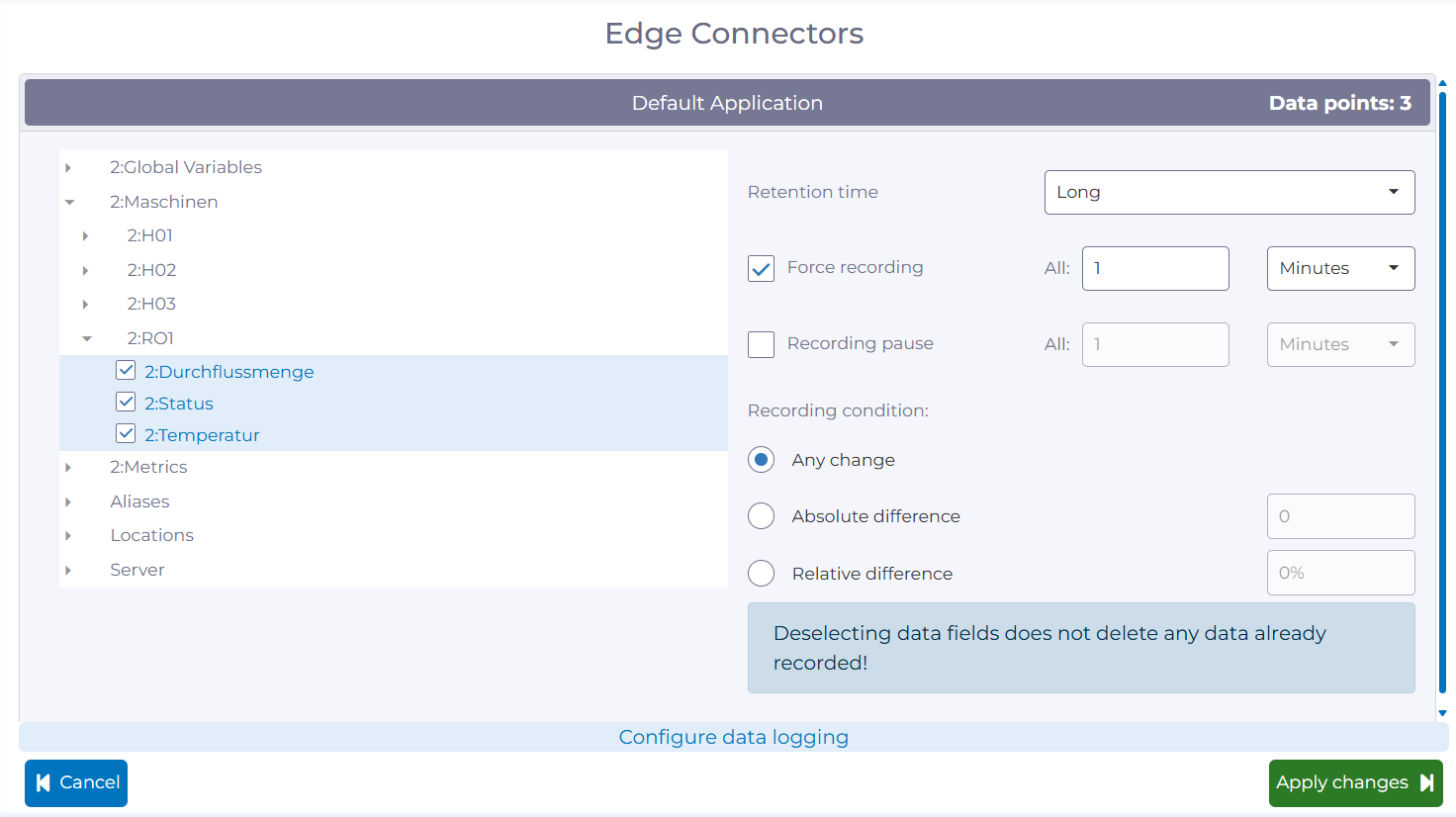

The illustration below shows how an OPC UA client application (in this case, the manubes cloud platform) accesses selected data points from an OPC UA server and records them at regular intervals.

OPC UA Data Recording with manubes

Many modern industrial controllers and other devices implement their own OPC UA servers and therefore offer native support for OPC UA. A popular example are the S7-1500 controllers from Siemens.

Older devices, for which the manufacturer does not provide a native OPC UA server, can still be integrated into OPC UA communication. Third-party OPC UA servers such as KEPServerEX support a wide range of vendor-specific interfaces and make data from different devices available via OPC UA.

Today, OPC UA has established itself as one of the most important standards in industrial automation. It is used to enable data exchange between devices and applications across different levels, independent of factors such as manufacturer or operating system which would have been limiting in the past.

OPC UA was released in 2008 as an evolution of the classic OPC standard (see differences). Since then, the OPC Foundation has continuously enhanced OPC UA and expanded it with new specifications.

Characteristics

Characteristics of OPC UA

OPC UA was developed by the OPC Foundation to meet industry-specific requirements for data exchange between a wide variety of systems.

As a result, the OPC UA communication standard is characterized by the following key characteristics:

Platform independence

In contrast to the classic OPC standard, OPC UA is no longer dependent on the Windows operating system. Previously, OPC servers and OPC clients had to be installed on Windows computers and communication between server and client was only possible via Microsoft’s COM/DCOM model. With OPC UA, data exchange takes place via the common Internet protocols TCP and HTTP(S). This means that OPC UA software can be installed on any system that supports Internet communication.

Flexbility and scalability

OPC UA enables standardized communication with a wide range of industrial systems – from the smallest devices to large distributed systems. New systems can therefore be integrated into an OPC UA-based infrastructure quickly and with comparatively few adjustments. This not only reduces the IT effort for individual solutions, but also offers greater scope for innovation by eliminating compatibility problems.

Complex information modeling

In contrast to the classic OPC standard, where individual variables are provided as tags, OPC UA supports comprehensive information modeling. This is based on so-called “nodes” and relies on concepts from object-oriented programming. Real objects and their status can be represented digitally. Methods can also be defined that can be called up by OPC UA clients in order to interact with devices and machines in a targeted manner.

Future-proofing

The OPC UA standard is being continuously developed by the OPC Foundation in order to meet the changing requirements of industry. An important requirement here is compatibility with current and future technologies in order to ensure that investments in industrial automation technologies are future-proof. Many definitions in areas such as data modeling and data transport have therefore been deliberately kept abstract to enable seamless integration of new technologies and innovations.

Security

The OPC UA standard defines various mechanisms to ensure security in industrial data exchange, including application and user authentication, message signing and encryption, and fine-grained configuration of access rights.

For more details, please visit our page on OPC UA Security.

Optimize your production with manubes

manubes offers a central platform for production data management, data visualization and workflow-based process automation.

Manufacturers gain access to a variety of innovative tools in order to quickly develop their own applications – tailored to their requirements.

Information Model & Specifications

Information model and specifications

OPC UA enables a wide variety of components, devices and applications to communicate with each other, overcoming the boundaries of the classic automation pyramid. This requires consistent structuring of information, i.e. data must be represented in a sensor in the same way as in a software system for data visualization.

In the following sections, we explain how OPC UA servers enable targeted data access to or control of industrial devices by OPC UA client applications.

OPC UA information model

In contrast to the classic OPC standard, OPC UA features a complex, node-based information model. Due to this, OPC UA is able to describe real objects digitally and provide units, hierarchies, relationships and configuration parameters in addition to values.

Real objects are represented as “nodes” in the OPC UA information model. These are assigned to specific types and have properties that can be read, e.g. the temperature measurement of a sensor.

References are used to display relationships to other nodes. Based on object-oriented programming, methods can be defined to interact with a node (reading and writing data points, operating systems, etc.).

Definitions of object types (and the associated attributes and methods) are summarized under a “domain”. The OPC UA basic information model of the OPC Foundation can be extended by other organizations by providing their own type definitions under a new domain. In this way, extended information models can be created for specific device types (e.g. pumps, scanners, etc.) or industries, which are always based on the basic model. OPC UA servers can optionally implement these information models.

OPC UA clients navigate domains and the associated address spaces in order to interact with specific nodes and retrieve the desired information.

The OPC UA standard is based on a service-oriented architecture: An OPC UA server implements information models and provides services (methods) that can be used by an OPC UA client.

OPC UA specifications

OPC UA is made up of various specifications. These define the functions and services that an OPC UA server implements and/or provides for OPC UA clients.

An OPC UA server does not have to implement all specifications.

The most important OPC UA specifications include the following:

Data Access: Enables an OPC UA client to locate nodes and read and write data.

Historical Access: Enables the retrieval or updating of historical data stored in an OPC server. Time periods can be specified or various statistical parameters applied.

Alarms & Conditions: Enables the receiving and processing of alarm messages and event logs by OPC UA clients.

PubSub: Describes the implementation of a publish-subscribe model in OPC UA communication. Here, the communication participants are divided into publishers and subscribers, which do not communicate directly with each other but publish (publishers) or retrieve (subscribers) information from a central broker.

Industrial Use

Significance of OPC UA for the industry

Open Platform Communications (OPC) (also known as “OPC Classic”), the predecessor of OPC UA, made a significant contribution to the industry when it was introduced in 1996: OPC made it possible to access data from machines by different manufacturers and make it usable for various applications. This offered possibilities for data visualization and process control that were previously only possible with a great deal of effort or a commitment to a single provider.

OPC UA still follows this basic idea. The UA specification solves the existing problems with the classic OPC standard and extends it with numerous functions and features that make OPC UA an essential part of industrial IoT communication.

Thanks to its interoperability, flexibility and scalability, the OPC UA standard is widely used in virtually all industrial sectors. Manufacturers of modern industrial devices are implementing their own OPC UA servers to facilitate integration into existing infrastructures. And many IT software providers are also integrating OPC UA client functionality into their applications.

OPC UA: Industrial use cases

One of the main goals in the development of OPC UA is compatibility across different industries, network architectures, device types and software applications.

The fact that OPC UA enables both field-level sensors and enterprise-level cloud platforms to use a unified data standard opens up many practical opportunities.

The traditional automation pyramid, where communication between field devices and ERP/cloud systems typically passes through multiple layers, is often bypassed with OPC UA. As an example, users of our manubes cloud platform are able to utilize OPC UA client functionality to directly transmit production order data to controllers.

At the same time, OPC UA helps with simplifying infrastructures and interfaces, reducing both maintenance and configuration effort.

1. Production control and monitoring

Many fundamental processes and data transfers in today’s industrial production are based on OPC UA. Common software systems such as MES and ERP platforms provide OPC UA client functionality, while machines and devices either implement their own OPC UA servers or are connected to external OPC UA servers.

This makes it possible to capture, visualize, and further process data from controllers and other sources using appropriate software (see also production monitoring). At the same time, order data and other parameters can be transmitted to controllers and similar field devices to control and automate processes.

2. Collecting data from multiple sites in the cloud

OPC UA also plays an important role in aggregating data across different sites.

Data from individual locations can be collected locally and transmitted to a higher-level enterprise cloud platform. Both the local aggregation of data and the transfer to the cloud can be carried out using OPC UA.

Advanced data architecture concepts such as the Unified Namespace (UNS) combine OPC UA for accessing data sources at the field level with MQTT for distributing data at the enterprise level.

3. Use in edge architectures

Thanks to its platform independence, OPC UA can also be deployed on sensors, edge devices, and edge gateways. This makes the standard highly relevant for edge computing, where data is processed in a decentralized manner close to its source.

Its flexibility and scalability, along with robust security mechanisms and standardized information models, are key reasons why OPC UA is widely adopted in many edge infrastructures.

Optimize your production with manubes

manubes offers a central platform for production data management, data visualization and workflow-based process automation.

Manufacturers gain access to a variety of innovative tools in order to quickly develop their own applications – tailored to their requirements.

Try manubes for free

Test the different manubes features in your personal cloud environment.