Definition, Calculation & Examples

Takt Time in Production

Takt time is used to align the production rate with customer demand. It helps with identifying bottlenecks and strategically allocating resources to individual workstations.

Takt time is a target value for the production rate and defines how quickly a single unit must be completed in order to meet customer demand efficiently.

It is used to align production speed with customer demand, avoid overproduction, and keep inventory levels low.

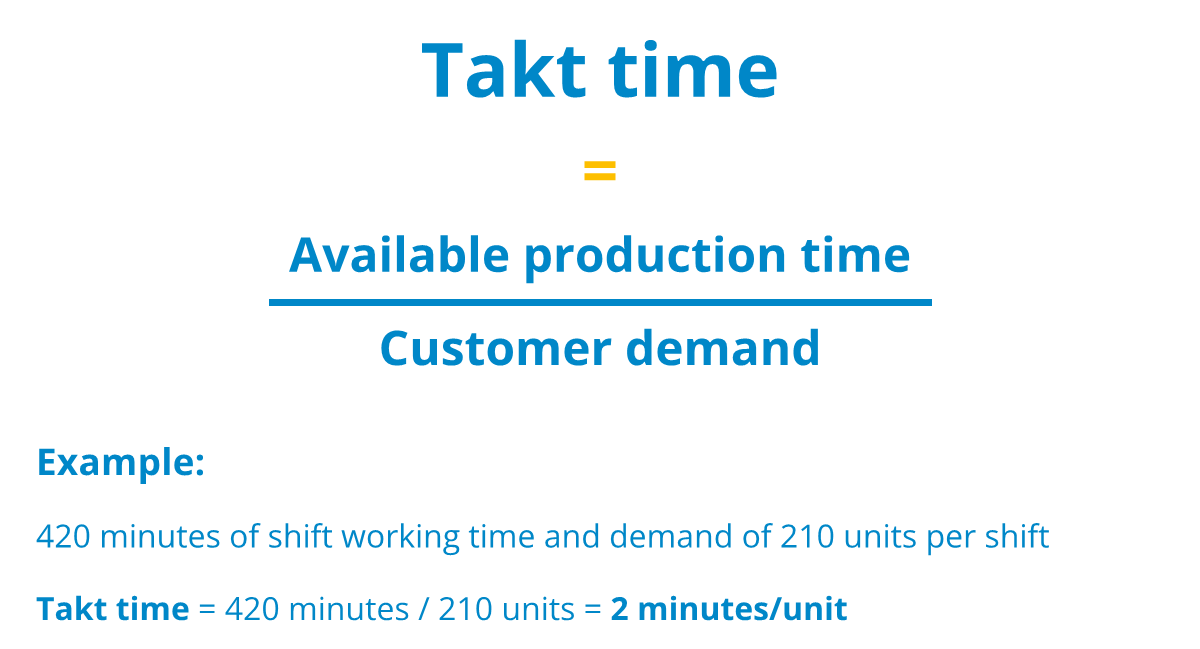

Calculating takt time

Takt time is calculated by dividing the available working time by the number of units demanded (target quantity).

The result is the optimal time for the completion of a single unit. If production takes longer than this (exceeding the takt time), customer demand cannot be fully met. If production is faster than the takt time, overproduction occurs.

The available working time per shift is calculated by subtracting break times, shift changeovers, planned maintenance, cleaning and similar activities from the total shift length. Customer demand can be determined from the production schedule, forecasts or existing orders.

Example for the calculation of takt time

- Available working time per shift: 420 minutes

- Demand (target quantity) per shift: 210 units

Takt time = 420 minutes / 210 units = 2 minutes/unit

To maintain a takt time of 2 minutes, the processing time at none of the successive workstations may exceed 2 minutes. Otherwise, the station is not capable of meeting the takt and becomes a bottleneck that limits the maximum production rate.

Suitability

Where is takt time used?

Takt time is used wherever production processes are regular and repeatable. This mainly applies to mass production and flow production, where large quantities of identical products are manufactured continuously. Takt times are also used in batch production, where identical products are produced in larger quantities.

In contrast, takt time is less suitable for highly customized products and processes (e.g. one-off production or job shop manufacturing).

Takt time plays an important role in the automotive industry. Car manufacturers use optimized takt times to synchronize the individual production steps along the assembly line with the goal of achieving a similar processing time at each station – trying to avoid waiting times, congestion and idle time.

Advantages

What are the advantages of using takt time?

Takt time is a tool used in production planning and serves as a basis for allocating resources and adjusting processes. Industries such as automotive commonly structure the entire production process around predefined takt times.

In addition, takt time supports production monitoring and the Continuous Improvement Process (CIP). When production runs to takt, problems can be identified more quickly (“Which workstation cannot meet the takt?”). Companies can then optimize bottlenecks, for example by allocating additional personnel to a specific workstation. Thus, takt time supports both quick reactions as well as long-term optimizations.

Key advantages of takt time:

- Alignment of production volume with customer demand

- Targeted allocation of resources to workstations

- Performance monitoring of individual workstations

- Identification of bottlenecks and optimization potential

- Standardized production rate as a benchmark

Monitor key production areas from anywhere

Unforeseen disruptions can prevent compliance with the takt time and cause significant damage.

With manubes, you are able to capture and visualize machine data to detect problems at an early stage and respond immediately. Customized, mobile-friendly dashboards provide maximum transparency across the entire organization – on PCs at headquarters, on monitors in the production hall or directly at the workstation.

Measures

How can the processing time of a workstation be aligned with the takt time?

In practice, companies try to align the processing time at each successive workstation in a manufacturing or assembly line as closely as possible with the defined takt time. Depending on whether a workstation is above or below the takt time, different measures can be applied:

Processing time exceeds the takt time (workstation is too slow)

- Multiple operators: Simultaneous processing of a product by multiple operators

- Parallel workstations: The workstation is duplicated so that two products can be processed at the same time

- Technical aids: Support of work steps through assistance systems, robots or similar technologies

- Reduce work content: Transfer partial tasks to upstream or downstream workstations

Example: The defined takt time is 60 seconds, but a workstation requires 120 seconds to process one unit. If additional capacity allows two products to be processed in parallel, the output rate of the workstation is exactly in line with the takt of 60 seconds per unit.

Processing time is below the takt time (workstation is too fast)

- Consolidation: Several short tasks are combined at one workstation to utilize available time

- Task transfer: Taking over work steps from upstream or downstream workstations

- Buffers: Planning intermediate buffers to compensate for fluctuations

- Capacity reduction: Reducing staffing levels or eliminating parallel workstations

Meeting takt times:

Strategies for efficient and transparent production

Real-time monitoring

of individual workstations

Visualize the performance of individual machines and workstations in real time and immediately see when a station is no longer producing in line with the takt. With manubes, you can capture data directly via OPC UA and other interfaces and integrate it into custom dashboards or overview pages – ready for display on any device. In addition, mobile notifications and alerts can be used to proactively inform responsible staff when defined thresholds are exceeded.

Collection and analysis

of large data sets

Capture and store performance data across all production areas to create a solid data foundation for long-term optimization. With manubes, you can manage data in custom data models, integrate it into dynamically generated production reports or transfer it to other systems. Existing data in data models can be analyzed using the AI assistant to identify and investigate potential bottlenecks within seconds.

Provision of ERP data

on the shop floor

Ensure that local teams are able to easily access relevant ERP data to avoid conflicts and delays in transport orders and similar processes. With manubes, you can display data from SAP and other systems directly at the workstation via custom user interfaces – clearly structured and mobile-friendly. Enhance UIs with checklists, forms and other interactive elements to optimize data exchange between the shop floor and the enterprise level.

Process optimization

through customized applications

Develop digital solutions to accelerate manual or paper-based processes. Integrate QR code scanning into workflows to automatically capture data or verify materials. With the manubes designers, you gain access to flexible no-code tools for building custom applications – consisting of data models, workflow automations and interactive user interfaces.

FAQ

Other frequently asked questions about takt time

What does a reduction in takt time mean?

A shorter takt time means that less time is available to produce a single unit. The result is a higher production rate and thus a larger number of units produced. To achieve this faster production pace, the processing time at every individual workstation in a manufacturing or assembly line must be equal to or below the takt time.

A shorter takt time typically means an increased workload for personnel and may lead to higher error rates. In addition, overproduction and higher inventory levels can occur if production output exceeds customer demand.

What does an increase in takt time mean?

An increased takt time means that more time is available to produce a single unit. As a result, the production rate is lower and the number of units produced per shift decreases.

Increasing the takt time can lead to improved product quality and reduced workload for personnel. However, if production can no longer keep pace with demand, delivery shortages may occur.

What is the difference between takt time and cycle time?

Takt time is a target value for the production time of a single unit and is derived from customer demand.

Cycle time, on the other hand, is the actual time a workstation requires to process a single part. It typically includes all process-relevant steps, but not waiting times outside the processing operation.

While takt time is calculated based on customer demand, cycle time can be measured directly, for example using data from a PLC.

In general, the goal is to align the cycle time of all workstations with the defined takt time.

What is the difference between takt time and lead time?

Takt time is the target time for producing a single unit (derived from customer demand) and defines the rhythm at which finished products should leave the line.

Lead time covers the total period a product requires to pass through the entire production process – from the start of the first processing step to the completion of the last.

In addition to processing times, lead time also includes setup times, transport times, as well as waiting and idle times.

Try manubes for free

Test the different manubes features in your personal cloud environment.