Many companies face the challenge that their production systems – especially older machines – offer limited or no capabilities for capturing production data in real time. The lack of transparency can hinder optimization, complicate decision-making and slow down innovation.

To keep up with necessary changes and remain competitive in the manufacturing landscape, companies need to be able to efficiently and quickly integrate existing equipment into a modern data infrastructure. This article shows you how to connect your legacy machines to your cloud platform via OPC UA with minimal effort, create transparency, and lay the foundation for future optimization and AI use.

Starting Point: Legacy Machines in Production

Many manufacturing companies utilize aging machinery. While many of these so-called legacy machines tend to be reliable, they lack modern communication interfaces.

Typical issues include:

- No network connectivity

- Proprietary or outdated protocols

- Lack of sensors for data collection

As a result, valuable information from the production process remains unused. Decisions are often based on estimates rather than concrete data. Optimization potential goes unnoticed.

The Path to Fast Integration: OPC UA as a Key Technology

OPC UA (Open Platform Communications Unified Architecture) has established itself as the standard for secure and platform-independent data communication in the industry. With OPC UA, older machines can now be efficiently connected to modern systems by using various technologies:

- Retrofit Sensors: External sensors measure relevant data such as temperatures, vibrations or production counts. Compact microcontrollers (e.g. Siemens Logo, S7-1200, WAGO PFC) then provide this data via OPC UA.

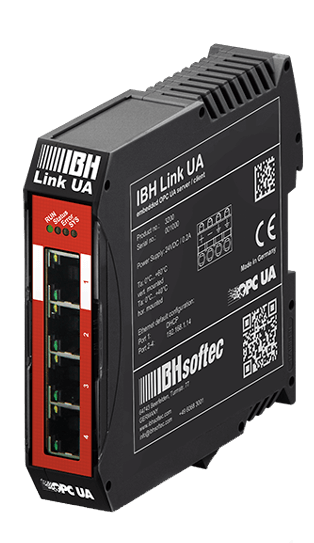

- Edge Gateways: These devices extract machine data (e.g. via serial interfaces or legacy control protocols) and convert it into OPC UA.

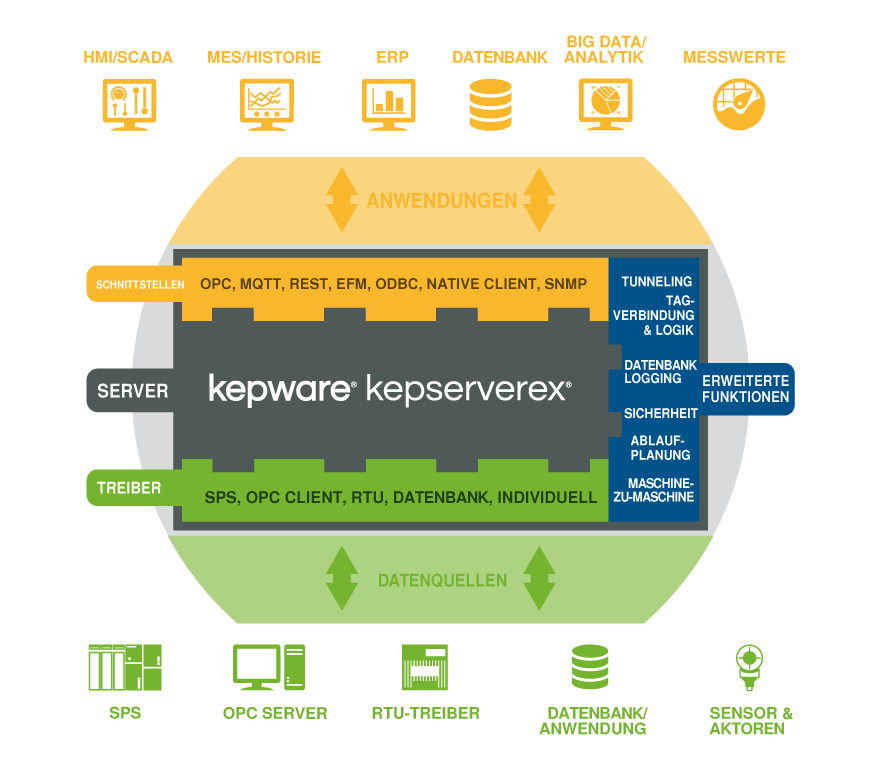

- Software Adapters: Third-party OPC UA servers (e.g. Kepware OPC Server) can access data from existing controllers using drivers for proprietary protocols and make it available.

Thanks to modular systems and preconfigured interfaces, integration can often be completed within a few days – without requiring extensive modifications to the machines themselves.

As soon as the equipment is OPC UA-capable, nothing stands in the way of integration into modern infrastructures.

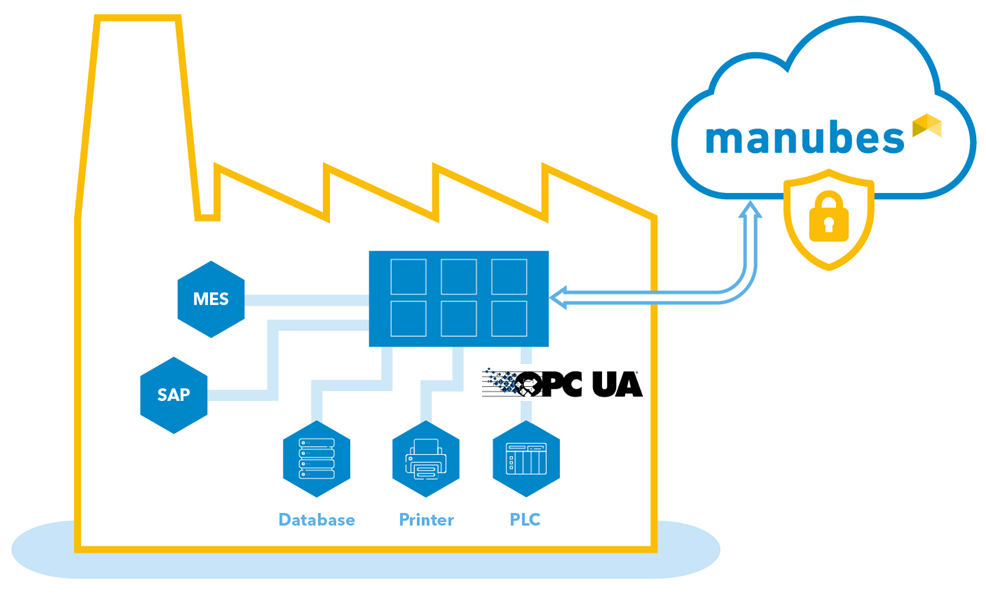

With manubes, OPC UA-capable machines, devices and systems can be connected quickly and securely to a modern cloud platform.

Bringing Data to the Cloud: Integration and Visualization

Through secure connectivity to cloud platforms like manubes, collected machine data can be centrally stored, processed and visualized.

Companies benefit from:

- Real-time dashboards for monitoring production KPIs

- Historical data storage for long-term analysis

- Custom alarm systems for early detection of deviations

Modern encryption technologies and scalable cloud architectures ensure both data security and the flexibility to expand on existing solutions.

More Than Just Transparency: The Road to AI-Driven Optimization

Machine data acquisition is not just a means for short-term transparency – it forms the foundation for long-term efficiency gains.

With the insights obtained, companies can:

- Establish predictive maintenance strategies to prevent unplanned downtime

- Detect quality deviations early and initiate countermeasures

- Analyze energy consumption and identify potential savings

In addition, structured production data lays the groundwork for the use of Artificial Intelligence (AI) and Machine Learning. Algorithms can detect patterns, provide optimization suggestions, and predict future developments. Open interfaces ensure that these systems receive the necessary data.

Conclusion: Making Old Machines Future-Ready

Older machines no longer need to be a “blind spot” in today’s production. With modern retrofit solutions and rapid OPC UA integration, companies can quickly create transparency, optimize production processes, and sustainably secure their competitiveness.

Those who invest today in capturing and utilizing their production data not only achieve short-term efficiency gains but also lay the foundation for innovation and growth in the age of Industry 4.0 and Artificial Intelligence.

Get Started

Would you like to learn how to quickly and securely connect your existing machines to the cloud?

Schedule a free consultation or request a live demo now – we’ll show you how easy it is to achieve transparency, even with legacy machines.

Optimize your production with manubes

Connect production systems to the manubes cloud and manage data and processes on a central platform. manubes uses edge technology and offers support for standard industrial interfaces such as MQTT, REST and OPC UA. Configure secure data transfers and make the most of your data.

Recent Comments